3D Printing Services

Get the Parts You Need in a Matter of Days

Whether you need prototypes or end-use parts, we’ve got the technology to make it happen

Which 3D Printing Technology is Right for You?

FDM 3D Printing

Durable, functional thermoplastics Durable, functional 3D printed parts for prototyping or end-use applications

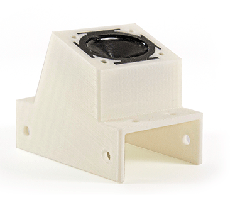

PolyJet 3D Printing

Rigid and rubber-like materials Rigid and rubber-like materials with a smooth surface finish

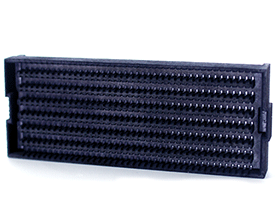

MultiJet 3D Printing

Highly accurate, best for small parts Highly accurate, ideal for very small, detailed parts such as electrical connectors

Why Choose 3 Space?

Here at 3 Space, our industrial 3D printing services are at the core of our product development pipeline. 3D printing allows us to quickly test new design iterations, produce jigs and fixtures on the fly, and even produce end-use parts in some cases. By providing our customers with access to a wide array of 3D printing technologies and materials, we can help you overcome a variety of challenges. Contact us today to learn how our 3D printing services can accelerate your development process and reduce your time to market.

Industrial Equipment

At 3 Space we offer a variety of 3D printing technologies on top-of-the-line industrial 3D printers.

Experienced Technicians

Our technicians have seen it all. We’ve 3D printed thousands of designs across every technology we offer.

Fast Lead Times

Lead time is the most important factor for most of our customers and we strive to deliver parts within 5 business days.

What can you do with 3D Printing

Cosmetic Prototypes

Evaluating the aesthetics of your design has never been easier. The smooth surface finish offered by PolyJet and MultiJet lets you simulate the look of injection molded parts.

Functional Prototypes

3D printed prototypes can be used to test the overall functionality of your designs. And with our durable FDM materials, you can test even the most demanding of applications.

Fit Testing

3D printing is a great way to ensure that all of your components fit together. We can even 3D print a variety of fasteners such as clasps, snaps, and threads.

Production Parts

Depending on the situation, 3D printing may be the best way to produce your final parts. For low-volume applications 3D printing may be more cost-effective than injection molding.

Jigs and Fixtures

3D printing is an ideal solution for custom production aids, such as hand tools for assembly. FDM materials can make parts durable enough for most applications.

Tooling

FDM 3D printing can provide a fast, cost-effective alternative for thermoform tooling. And PolyJet and MultiJet can be used to create master patterns for casting.

3D Printing Advantages

Lower Cost

With no expensive tooling or setup costs, 3D printing offers substantially lower unit costs for low volume runs.

Faster Lead Time

Since there’s no need for the creation of molds, custom fixtures, or other tools, 3D printing allows you to get a part in a matter of days, rather than weeks.

Complex Geometry

Because 3D printing is in additive process, it is capable of producing more complex geometry than traditional manufacturing.

3D Printing Technologies

3 Space offers a complete selection of 3D printing technologies for any application. Our comprehensive 3D printing services give you access to a complete range of both rigid plastic and flexible, rubber-like materials. We can produce parts with a smooth surface finish for cosmetic prototypes, or we can produce parts from durable thermoplastics for more demanding applications.

FDM 3M Pricing

Because they are made with standard thermoplastics, FDM parts are durable and heat resistant. FDM is great for functional prototypes, fixtures, and end-use parts. Available FDM materials include ABS, Polycarbonate, Nylon, and Ultem..

- Large build volume

- Extremely durable materials

- Ideal for functional parts

- Layers as low as 0.005”

3D Printing

PolyJet produces detailed prototypes with a smooth surface finish. PolyJet parts can be printed in both plastic and rubber-like materials. Polyjet can even print a single part out of multiple materials, allowing features such as gaskets or overmolding to be simulated

- Rigid and rubber-like materials

- Multi-material parts

- Smooth surface finish

- Layers as low as 0.001”

MultiJet 3D Printing

MultiJet has the highest resolution and tightest tolerance of the 3D printing technologies we offer. It is ideal for parts requiring a high level of detail. Parts produced via MultiJet have an ultra smooth surface finish to simulate the injection molding appearance.

- Great for small, detailed parts

- Exceptionally accurate

- 1600 dpi resolution

- Layers as low as 0.0006”