Overview

MultiJet 3D printing is a material jetting technology that prints parts from photopolymer resin which is cured by UV light. It offers low layer heights and high XY resolution, making it the highest resolution 3D printing technology we offer. Additionally, with its higher heat resistance compared to PolyJet and its simulation of production plastics, this type of printing is suitable for both prototypes and functioning parts.

When designing parts for MultiJet printing, as with any other 3D printing technology, there are several important factors to consider. This guide will advise you on best practices when designing specifically for MultiJet and help make sure your parts print right the first time.

The Printing Process

As with all other 3D printing technologies, MultiJet slices your design into hundreds or thousands of cross-sectional layers. These layers are reproduced one at a time until your part is complete.

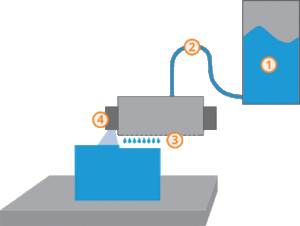

To create each layer, material is melted and emitted as droplets through a print head with a grid of hundreds of holes. The printer head moves over the build tray much like that of an inkjet printer to build the design layer by layer. A UV light passes over each layer after it is completed, hardening the material into a solid plastic. This process is repeated until the part is complete and ready for post-processing.

To create each layer, material is melted and emitted as droplets through a print head with a grid of hundreds of holes. The printer head moves over the build tray much like that of an inkjet printer to build the design layer by layer. A UV light passes over each layer after it is completed, hardening the material into a solid plastic. This process is repeated until the part is complete and ready for post-processing.

MultiJet, like PolyJet, has a wax-like support material that is used to support the design as it is printed. Where this differs from PolyJet is that this support material may be melted away in an oven, rather than removed manually. This allows for designs with small or blind cavities that would be impossible to clean if printed with PolyJet. After the support material is melted away, the design goes through a three-step process, which includes an ultrasonic bath, a cleanse for residue, and a final rinse.

Designing for MultiJet

When designing parts for MultiJet, it is important to note the following specifications of our MultiJet printers:

Build Volume

The build volume of our MultiJet printers is 11.75”x7.3”x8.0”. While this is the largest item the MultiJet printer may make at one time, your design can be split into two or more sections, each smaller than the printer’s build volume and then glued together in post-processing.

Layer Heights

The three available layer heights for MultiJet are 0.0013”, 0.0011”, and 0.0006”. Depending on the height chosen, this may affect resolution and quality of the printed design, as well as lead time.

Tolerances

MultiJet is the highest-tolerance 3D printing technology we offer by a wide margin. The tolerance for MultiJet parts is ±0.001-0.002” per inch, one fifth of that offered by PolyJet.

Infill Types

The control software for MultiJet printers only supports solid infill. Solid infill ensures the stability and durability of your parts. Other types of infill can be added manually before the design is sent to print. However, making a design with another infill type on a MultiJet printer will likely result in the rest of the part’s interior being filled in with support material.

Part Orientation

With MultiJet, part orientation matters very little. Because MultiJet prints in such high detail, little to no layer lines are visible. The only time this might be an issue is with long curved surfaces, and even then, it will be minute. The footprint of your design does not have any bearing on the outcome either as long as it fits within the aforementioned build volume. The difference will just be how much support material is needed to complete the design, which may affect the lead time of the item slightly.

Feature Designs

As for specifications for the features of your design, we recommend the following best practices:

Wall Thickness

Since MultiJet produces rigid plastics similar to production plastics, too thin wall thicknesses can decrease a part’s life by making it brittle, especially if the design is used or handled frequently. We recommend walls be no thinner than 0.04”. For designs used frequently, wall thicknesses of 0.06” and greater are recommended.

Holes/Pins

For a proper fit between your design’s holes and pins, we recommend either under-sizing the pin OR over-sizing the hole by at least 0.005” to account for the printer’s tolerance. Furthermore, for larger designs, extra clearance is advisable due to tolerance stacking.

If your design requires pins, make sure to consider the strength your design will need. Small fragile pins will be a weak point in your part. To avoid pins that are too thin, we recommend making no pin thinner than 0.04”.

Fillets/Chamfers

Fillets/Chamfers

Thanks to its high resolution, MultiJet can easily reproduce sharp corners as well as filleted and chamfered edges.

Bosses/Ribs

For additional support, especially if your part has thin walls, bosses and ribs can be added to your design. These support structures will work best if placed in areas where more strength will be required, such as long thin walls or where there is a freestanding feature that must be supported. Follow the above MultiJet wall thickness recommendations when adding bosses or ribs.

Threads/Fastening Hardware

A design that uses threads will require extra consideration to ensure the right fit. We recommend starting with an extra 0.005” of wiggle room on your threads in your first revision and then tightening them up if need be.

We also recommend designing your threads with rounded crests and roots, but this is not as important. MultiJet can produce a slightly crisper and more durable thread than PolyJet due to its increased definition and use of materials with production plastic characteristics.

For fastening hardware, MultiJet can easily accommodate heat-set inserts. This is because the materials used in production are thermoplastics than can melt to allow the heat-set insert to be placed and solidify around the insert. Additionally, you can use MultiJet for snap fit designs as long as you account for the stacking tolerances.

Assemblies

MultiJet is capable of 3D printing moving assemblies as a single part. It is recommended that you maintain 0.005-0.01” between each component of the assembly to ensure proper printing and function.

Text

Like PolyJet, MultiJet can produce excellent raised and recessed text with ease. We recommend that you refer to the wall thickness specifications above to design your text. If the text is thinner than the minimum recommended thickness, problems, such as breakage and support material getting stuck, can occur.

MultiJet at 3 Space

Here at 3 Space, our MultiJet 3D printers are of the highest quality and can take your design to the next level. Our technicians have specialized in 3D printing for years now and will provide the highest quality of care for your design.

Contact us today to learn more about our MultiJet 3D printing services.