Dual-shot plastic injection molding, sometimes simply referred to as overmolding, is an efficient manufacturing process that allows you to produce your multi-material and/or multi-color part in one mold cycle without extra assembly steps. While it is possible to mold more than two materials/colors this way, this article will focus on using only two materials at a time for simplicity of discussion.

What is Dual-Shot?

What is Dual-Shot?

Dual-shot plastic injection molding, also called multi-shot, double-shot, and two-shot, is a type of overmolding where separate nozzles on one machine are used to form a multi-material or multi-colored part during one mold cycle. This allows you to efficiently create single parts with different regional mechanical properties, hardnesses, or colors.

How It Works

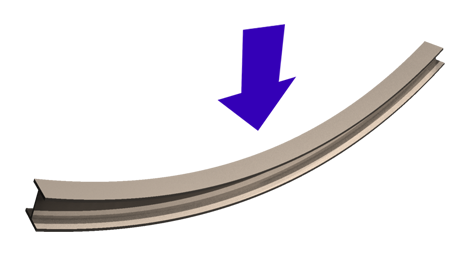

Dual-shot is best understood in terms of layers, and each layer is a different material or color that is created by a separate nozzle on the injection molding machine. The first material is injected into the mold to create the first layer, or substrate, that serves as the core for the sequential material to bond around. This initial layer is allowed to solidify and cool before being transferred to the other chamber of the mold. Transfer can be done by hand or robot arm, or, if the mold is on a rotary platen, the mold will open and the half bearing the substrate will rotate 180° to meet the other mold chamber and nozzle. Once the substrate is in place in this new chamber, the second material is injected. This allows the second layer to form a molecular bond with the first and create a strong hold. After this layer cools, the final part is ejected.

It is important to note that this process may be slowed or sped up by the transfer method used. Hand and robot arm transfer take a few seconds longer than rotary platen movement. While rotary platen molding is more expensive, it may prove to be more efficient if you are producing your part in high volumes. Additionally, your materials and mold design should be carefully evaluated to ensure that the materials will bond to each other correctly and that the mold aligns correctly to prevent flash, misalignment, or other deformities.

Finally, the substrate to be used as the core may also be a pre-made metal or plastic insert. In this case, the general term of overmolding is more frequently used since the substrate is not produced in the same mold cycle as with dual-shot.

Applications

Applications

Dual-shot injection molding is used to create many products for a wide range of industries, including automotive, medical, consumer goods, and more. Its ability to layer different colors and types of materials allows for versatile parts. Primarily, this versatility emcompasses the following:

- Soft touch components over hard substrates (toothbrushes, power tools, etc.)

- Movable or flexible regions (buttons, hinges, snaps, etc.)

- Watertight and airtight features (seals, gaskets, caps, enclosures, etc.)

- Surface identification (logos, symbols, text, etc.)

Benefits of Dual-Shot

There are many advantages to using dual-shot injection molding for your part’s production. As a whole, these can be grouped into three primary categories:

Efficient & Cost-Effective

Although the upfront costs of this injection molding type can be expensive, especially if using a rotary platen, dual-shot may actually cut costs in many areas of your production. Machine operating cost and worker labor are the main points of cost savings because one machine makes the whole part and post-processing assembly is not required to make the part functional. This can cut down cycle time drastically, which will also help keep costs to a minimum.

Improved Lifespan

Improved Lifespan

Elimination of assembly steps and other areas of worker interaction means dual-shot’s accuracy and repeatability are higher than other molding processes. The part’s components are consolidated in dual-shot molding by bonding, and transition from one material to another appears more smooth. As such, these elements effectively make the finished piece more durable than individual parts assembled to make the same piece.

Design Flexibility & Innovation

More advanced functionality and aesthetics can be achieved with dual-shot. This is due to the ability to overlap multiple materials and colors. By doing so, you can create parts with regional differences for an enhanced part that more accurately fulfills its purpose and your vision. Additionally, this allows engineers to create parts that would not be possible with other molding methods, meaning more efficient parts are possible to design.

Injection Molding at 3 Space

Here are 3 Space, we offer multiple manufacturing methods, including regular plastic injection molding as well as overmolding. If you are interested in learning more about how overmolding can aid in your part’s production, our engineers are happy to answer any questions you have. For more information, contact us today.