3D printing can be a great way to manufacture your parts. Particularly, when used on an as-needed basis, it can help increase efficiency and better cater to demand. In this article, we’ll discuss how on-demand 3D printing works, the pros and cons of it, and if it’s right for you.

How On-Demand 3D Printing Works

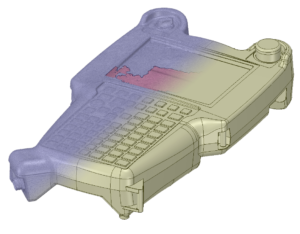

3D printers use STL files, or generic CAD models, as the instructions to properly print your part. Like any other digital files, once created, these files can live on a computer indefinitely and take up little space. A collection of these files may be referred to as a virtual library. With on-demand 3D printing, you simply choose one of these design files from your library, send it to the appropriate 3D printer, and wait for the printing process to begin. Depending on the size of the chosen part, the print may be completed within a few hours to a few days. As such, parts can be produced on an as-needed basis.

3D printers use STL files, or generic CAD models, as the instructions to properly print your part. Like any other digital files, once created, these files can live on a computer indefinitely and take up little space. A collection of these files may be referred to as a virtual library. With on-demand 3D printing, you simply choose one of these design files from your library, send it to the appropriate 3D printer, and wait for the printing process to begin. Depending on the size of the chosen part, the print may be completed within a few hours to a few days. As such, parts can be produced on an as-needed basis.

Advantages of On-Demand 3D Printing

On-demand 3D printing is great for increasing the efficiency of production while keeping costs low. Here are some specific examples of how on-demand 3D printing does this:

1. Rapid Turnaround Time

Due to the additive nature of the 3D printing process, a 3D printer takes very little setup in order to be able to print your part. This means parts can be produced quickly whenever you need them, enabling you to meet tight deadlines.

2. Reduced Physical Inventory

2. Reduced Physical Inventory

Physical inventory can take up a lot of space and resources. This is especially true if the inventory is not moving fast. If this is the case, inventory may easily become outdated and obsolete, leading to useless inventory that drains resources or ends up in a landfill. Due to tooling costs, traditional manufacturing methods, like injection molding, typically require that you order a part in bulk to be financially viable. This may lead to an overstocked inventory. However, due to having no tooling and no minimum order quantity required, 3D printing allows for low volume runs at a fraction of the cost with short notice. As such, you can produce parts in the exact quantity you need when you need them so that your physical inventory is reduced.

3. Flexible Design Change & Customization

The design of a part may need to be modified or otherwise updated over time to meet changing needs. It can be difficult to justify these changes if you have already invested in tooling or inventory for the original design. But, because on-demand 3D printing works straight from your virtual library with no tooling, you can make these changes at little to no additional cost. This also allows you to customize each part if you wish.

Disadvantages of On-Demand 3D Printing

Although on-demand 3D printing offers significant benefits, there are a few drawbacks as well:

1. Low Volume

Low Volume

3D printing is not yet optimized for large volume productions, so ordering large quantities on-demand is not possible. If you need moderate to large quantities of your part, it may be best to use traditional manufacturing methods.

2. Issues with Order Fulfillment

There is a certain risk to manufacturing your part on short notice. This can be a drawback based on factors you may not be able to anticipate or control, such as the print failing or otherwise not being completed on time, severe weather hampering shipping, and more. There is very little room for error when using on-demand 3D printing, and when such problems arise, it can mean not fulfilling the order on time. Issues with order fulfillment with on-demand 3D printing may also come if there is a spike in demand for your part.

Is On-Demand 3D Printing Right for You?

Whether or not on-demand 3D printing is the right fit for your production needs will greatly depend on the core business principle of supply and demand. Knowing the demand for your part will better help you manage the supply and determine if printing the part on-demand is feasible.

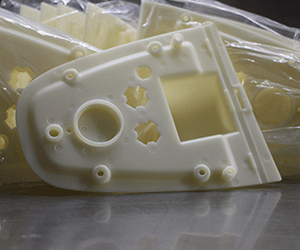

3D Printing at 3 Space

Here at 3 Space, we offer multiple 3D printing options to fit your manufacturing needs. With our top-of-the-line 3D printers and expert engineers, you can be assured that your part is in the best hands. For more information or to request a quote, contact us today.