Advanced Solutions

You have a myriad of choices when it comes to selecting a vendor for the variety of services we offer. But at 3 Space, our team is intimately familiar with the assorted challenges and constraints of developing a product and we’re more than capable of helping you overcome them. We know what matters to you and we want to help you get it.

New Product Development

If you have an idea or need for a new product or part, but lack the tools or technical knowledge necessary to bring your project to fruition, 3 Space can help. With state-of-the-art design software and our advanced manufacturing capabilities, our engineers can take your project all the way from a napkin sketch to a market-ready product.

Whether you’re creating a brand new product, improving on an existing product our knowledgeable engineering staff can bring your ideas to life. If you’re making a form-fitting part, such as aftermarket accessory, our 3D scanning services can ensure a tight fit from the first design revision. And with our in-house 3D printing services, we can prototype your design and quickly make revisions.

Legacy Part Re-Creation

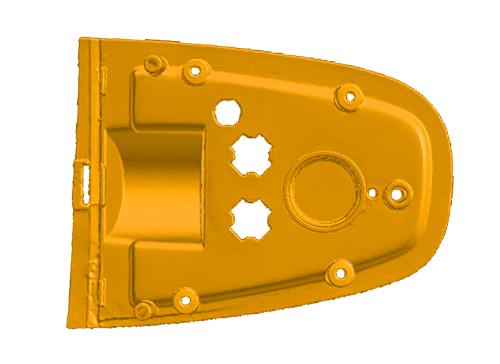

You might currently be manufacturing a part that you don’t have the original CAD for. Maybe the design predates CAD software or maybe you acquired the part in an acquisition. If you have parts like this you might find yourself needing CAD for them, either to modify the original design, or to use as a reference when addressing production issues or just to add to your archive for future use.

With our 3D scanning and reverse engineering services, we can easily turn your production parts into ready-to-use CAD. We can even get CAD from damaged parts, or from your tooling if you don’t have parts available. We can then 3D print the resulting CAD to ensure accuracy and roper fitment.

Let’s Design Something

Contact us today to discuss your project with a member of our engineering team.

Discontinued Part Re-Creation

Replacements parts for older industrial equipment are often discontinued, making them overly expensive or difficult to source. With our 3D scanning and reverse engineering services, we take the parts you need, even if they are broken or damaged, and turn them into a manufacturable CAD model. We can then produce as many copies as you need with our machining and molding services.

You can leverage the same workflow if you’re in the business of making aftermarket replacement parts. We can 3D scan and reverse engineer the OEM parts to generate a CAD model and then 3D print prototypes to ensure they fir properly with any other OEM parts.

Custom Manufacturing Aids

We can help you quickly create manufacturing aids such as go/no-go fixtures, assembly jigs, CMM fixtures and more. Our engineers can easily produce a cost-effective design for any application and produce a 3D printed prototype to test. If you only need a small number of parts, we can 3D print them rather than machining or molding. This is convenient because there is no investment in tooling so design changes can be made on-the-fly.

We can also help design accessories for your manufacturing equipment that can help reduce wear and eliminate costly shutdowns. With our 3D scanning and reverse engineering services, we can create a CAD model of critical components or areas of your equipment to use as a reference and design a form-fitting part around it.