3D Scanning Services

Get Results in as Little as 48 Hours

What can 3D scanning do for you?

Reverse Engineering

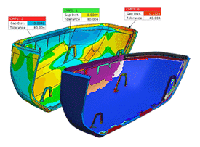

Dimensional Inspection

3D Scanning Technologies

How do our 3D scanning services work?

1. Receive Parts

First you’ll have to ship us your parts or drop them off if you’re local to us.

2. 3D Scanning

Once we receive your parts, we’ll scan them with our high-resolution 3D scanners.

3. Other Services

We can use the results of 3D scanning to either reverse engineer your part or perform an inspection.

4. Deliverables

Finally, we’ll send you the mesh produced by 3D scanning as well as the CAD for your part or the inspection report.

Our 3D Scanning Technologies

| Faro Laser Scanner | |

|---|---|

| Probe Accuracy | 0.0013 in |

| Scan Accuracy | 0.0021 in |

| Output Formats | STL | PLY |

| Blue Light Scanner | |

|---|---|

| Min Feature Size | 0.0020 – 0.0080 in |

| Scan Accuracy | 0.0003 – 0.0009 in |

| Output Formats | STL | PLY |

Get CAD from Your Parts by the End of the Week

Get a Quote for Reverse Engineering Today

3D Scanning Advantages

3D scanning is the fastest way to accurately capture the geometry of a physical object, making it ideal for quickly identifying problems with production parts. And nothing is faster or more effective than 3D scanning for creating 3D models from a physical object.

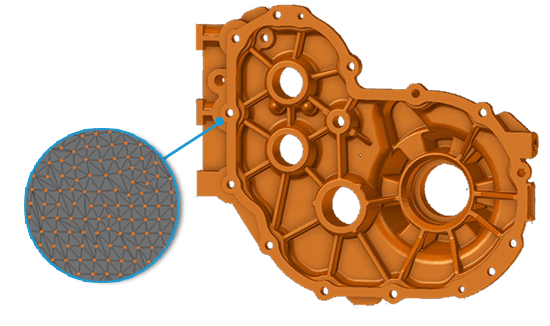

Our full-color, high-resolution 3D scanners are capable of capturing the most detailed features of an object, providing detail and accuracy that other methods cannot. The resulting 3D model retains the exact contours and dimensions of the object, enabling you to use the file to modify the design, compare the scan to the original CAD, create form-fitting aftermarket parts, or recreate a discontinued product that might no longer be on the market. The models produced by 3D scanning are readily 3D printed and machined. They can also be converted to parametric CAD with our reverse engineering services.

High Resolution

Captures perfect detail with a scan resolution of 0.1mm and point accuracy of 0.05mm

Any Sizer

Capable of capturing objects as small as a coin and larger than a car

On-Site

3D scanning can be performed at your facility by a member of our engineering team

Full Color

Scans objects in full color, with 24-bit, 1.3MP textures

Any Shape

Easily captures both mechanical and organic geometry

Non-Contact

All scanning is non-contact and non-destructive

What kind of parts can we 3D scan?

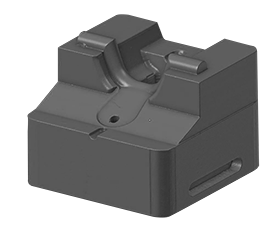

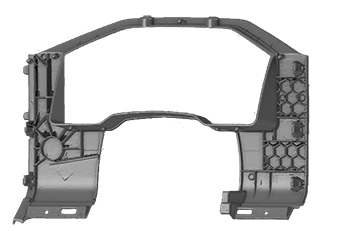

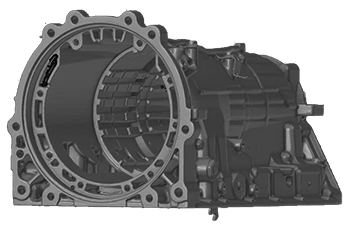

Molded Parts

Cast & Stamped

Tool & Mold