The Stages of Product Development

Developing a concept into a product may seem daunting, especially since some projects can take weeks, months, or even years to complete depending on their

Developing a concept into a product may seem daunting, especially since some projects can take weeks, months, or even years to complete depending on their

Successful product development can lead to a variety of benefits. Before these benefits can be enjoyed, however, certain challenges must be addressed during the development

Careful product development can yield a desirable, competitive product for the market. While multiple external factors may still influence the product’s level of success, a

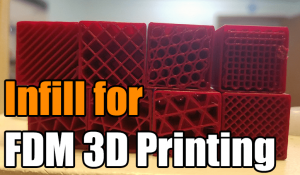

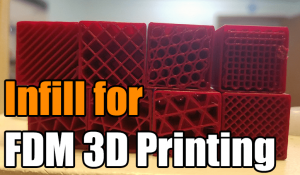

FDM 3D printed parts are not always made solid. Rather, with this printing method, parts can be made varying degrees of hollow to help control

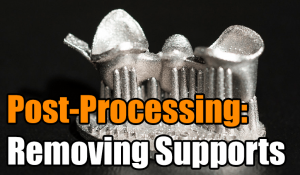

This blog post is part of our Post-Processing series. For more information on post-processing, check out our articles on removing supports and assembling and smoothing.

This blog post is part of our Post-Processing series. For more information on post-processing, check out our articles on removing supports and coloring and coating. Post-processing

This blog post is part of our Post-Processing series. For more information on post-processing, check out our articles on assembling and smoothing and coloring and

3D printing can be a great way to manufacture your parts. Particularly, when used on an as-needed basis, it can help increase efficiency and better

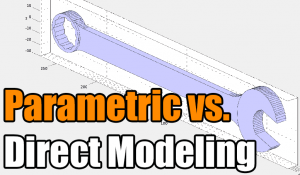

There are two approaches to creating CAD: parametric modeling and direct modeling. Both are useful for different aspects of the design process and can make

When it comes to 3D digital models, it can be a bit confusing to know which model or file type you need. The two