Dimensional Inspection

Compare parts to their original CAD

- Fulfill your FAI/PPAP requirements

- Perform ongoing quality control

- Troubleshoot out-of-spec parts

- Identify tooling wear before it happens

Get a report in as little as 48 hours!

How does dimensional inspection with 3D scanning work?

1. 3D Scan

Once we receive your parts, we’ll scan them with our high-resolution 3D scanners.

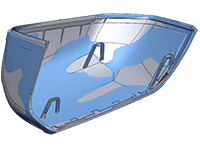

2. CAD Overlay

After your parts are scanned, we’ll align them with your original design in our analysis software.

3. Inspection

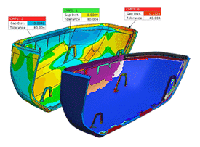

We then perform the dimensional inspection, generating a deviation map and callouts for critical dimensions.

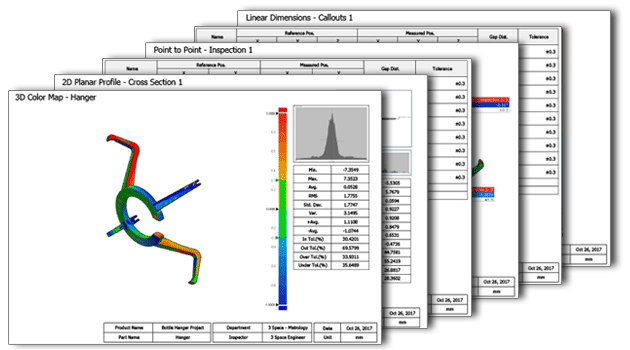

4. PDF Report

Finally, we will generate a custom PDF report listing all of the data we’ve gathered.

What are the applications?

First Article Inspection

We can help you get the data you need to meet your FAI requirements. Send us your production prototypes and we’ll generate a data-rich report comparing them to your original CAD.

Production Sampling

By regularly analyzing a sample of production parts, you can ensure the quality of your current parts and identify any trends before they become a problem.

Multi-Cavity Part Inspection

We can 3D scan parts from each cavity of your mold and compare them to the original CAD, ensuring that parts from each cavity are within spec.

Mold Wear Analysis

We can 3D scan your molds or other tooling and compare the 3D scan to the original design and identify any areas that may have become worn and need repair.

Which 3D Printing Technology is Right for You?

Part-to-CAD Comparison

Part-to-Part Comparison

Tooling Inspection

What types of analysis can be performed?

Deviation Map

Point Inspection

2D Planar Profile

What are the deliverables?