Reverse Engineering

Turn parts into CAD with 3D scanning

- Replace hard-to-find parts

- Digitize handmade prototypes

- Get CAD for legacy parts

- Speed up your product development

Get your CAD in as little as 48 hours!

How does reverse engineering from a 3D scan work?

1. Receive Parts

First you’ll have to ship us your parts or drop them off if you’re local to us.

2. 3D Scanning

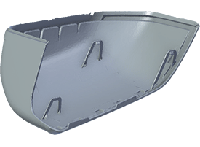

Once we receive your parts, we’ll scan them with our high-resolution 3D scanners.

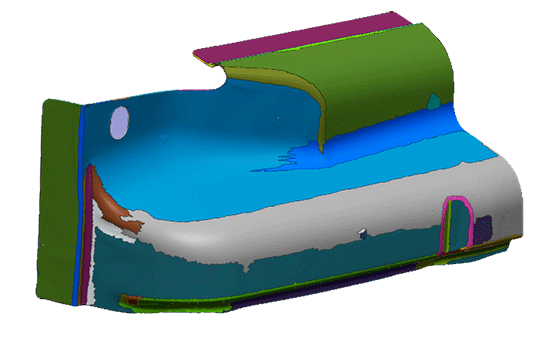

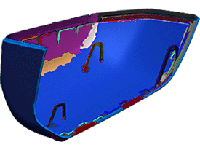

3. Reverse Engineer

We’ll then reverse engineer your parts, essentially recreating the CAD using the scan as a template.

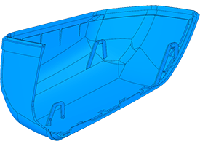

4. CAD File

The end result is a STEP or IGES file that can be used for manufacturing, modification or documentation.

What are the applications?

Replacement Parts

Hard-to-find replacement parts can be 3D scanned and reverse engineered to create a manufacturable CAD model.

Legacy Parts

If the CAD files or drawings for your parts no longer exist, we can recreate them from the physical part.

Aftermarket Parts

Form-fitting aftermarket parts can be designed around the reverse engineered model of an OEM part.

Handmade Prototypes

Handmade prototypes such as sculptures with organic geometry can be digitized with reverse engineering.

Design Modification

Reverse engineering will allow you modify the design of a physical part that you don’t have CAD for.

Computational Analysis

Computational analysis methods such as FEA or CFD require CAD models.

Why do I need to reverse engineer?

All 3D models are not created equal