Injection Molding

Production Plastic Parts

- Average lead time 25 days

- Virtually any moldable plastic

- Low and high volume, 250 – 10,000+ parts

- No setup fees

Overseas Injection Molding

While stateside molding is available upon request, we do the majority of our injection molding with a Chinese partner. Many people have understandable reservations about manufacturing in China. Below are the most common questions we receive.

Why manufacture in China at all?

The short answer is cost. Just buying tool steel in the US is more expensive than buying the steel and cutting the mold in China.

Is my intellectual property safe?

We account for more than 50% of our Chinese partner’s revenue. It is simply not worth the risk to them to begin selling counterfeit products.

Can you ensure part quality?

We receive samples from every mold before production begins. These parts are inspected to ensure they are within tolerance.

Parts as fast as 25 days

The standard lead time for an injection molding project is 25 days. This starts from the time we send the validated design to our molding partner and does not include time spent validating and modifying the design.

Any moldable plastic

We know every part is unique and may require a material with specific properties. That’s why we don’t limit our customers to a small selection of materials. We’ll make your parts out of any material that can be injection molded.

250 – 10,000+ parts

We can do both low and high volume production runs. If you only need a limited number of parts, our MOQ is only 250. This does not apply to first article runs.

No setup fees

When producing parts in low volumes, mold setup fees can have a significant impact on your unit cost. We’ll help you minimize costs by waiving setup fees, regardless of your order’s size.

3 Space Adds Value

Design Assistance

No CAD, no problem. Our experienced engineering team can help turn your concept into a manufacturable design. We’ve had hundreds of unique parts pass through our doors and we know what it takes to bring a project to production.

DFM Feedback

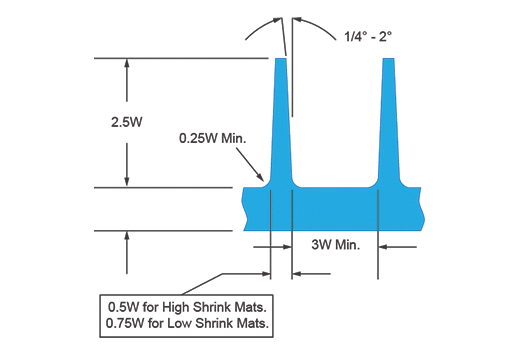

If you already have CAD, we’ll make sure it’s ready to be molded. Every part we receive is evaluated for manufacturability before we begin machining the mold. We check wall thickness, draft angles, feature size, and more.

Material Selection

Whatever the requirements of your application, we can help you select and source the right material. We can help find a material with your exact mechanical properties, heat resistance, chemical resistance, and ESD.

First Article Inspection

We use our advanced in-house 3D scanning technologies to perform a first article inspection on every part we injection mold. This includes a comprehensive report verifying that your parts are within tolerance.

Advanced Molding

Overmolding

Overmolding allows you to add soft-touch materials like TPE to buttons, grips, and other components on an otherwise rigid part. You

Two-Shot Molding

With two-shot molding, you can manufacture multi-color or multi-material parts in a single mold. This can help minimize assembly cost and make an overall stronger part.

Finishing Options

Color Matching

We can match the color of your parts to any provided color value. Provide us with a Pantone, RGB, or CMYK color and we’ll find a colorant to match.

SPI Finishes

After your tooling is machined, the mold can be finished to any SPI standard. We can sand away any tool marks or polish to a high gloss, whatever your project requires.

Textures

We offer hundreds of textures that can be applied to your entire part or just certain sections. These include pebbled, wood grain, haircell, and more.

Post-Processing

- Inserts

- Pad printing

- RFID shielding

- Assembly

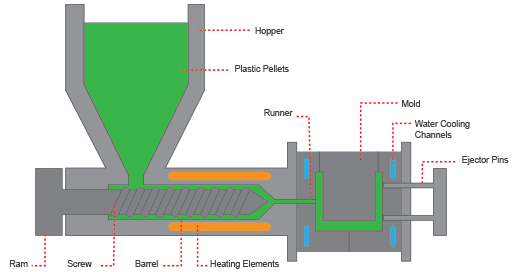

How Injection Molding Works

Injection Molding Design Guide

- Wall thickness

- Draft angles

- Ribs and gussets

- Mold sink