Today’s mass manufacturing processes create everything from the cell phones we carry to the cars we drive and make these products with extreme accuracy and uniformity. This would not be possible without the use of jigs and fixtures. In this article, we cover the difference between jigs and fixtures, their benefits to the manufacturing industry, and how producing your jigs and fixtures via 3D printing may be more efficient than traditional manufacturing.

What Are Jigs and Fixtures?

Jigs and fixtures are custom-made manufacturing tools that help control and automate the production process. The terms are often confused and used interchangeably, but the exact differences may be defined as follows:

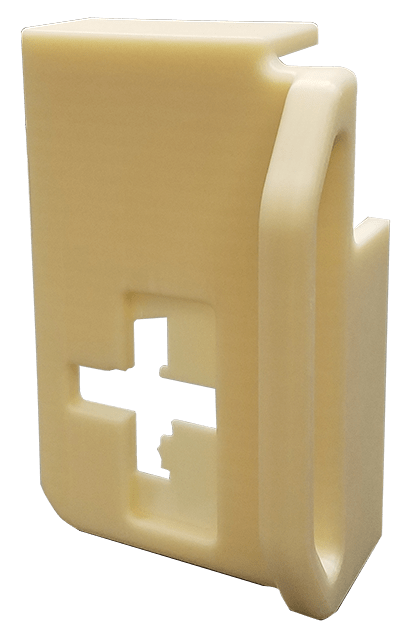

A jig is a guiding tool that directs and positions other manufacturing tools so that cuts, holes, and more can be made accurately on every production part. Most commonly, jigs are used to ensure the correct placement of drilled or tapped holes. Jigs help eliminate problems with components being misaligned or otherwise not fitting correctly.

A jig is a guiding tool that directs and positions other manufacturing tools so that cuts, holes, and more can be made accurately on every production part. Most commonly, jigs are used to ensure the correct placement of drilled or tapped holes. Jigs help eliminate problems with components being misaligned or otherwise not fitting correctly.

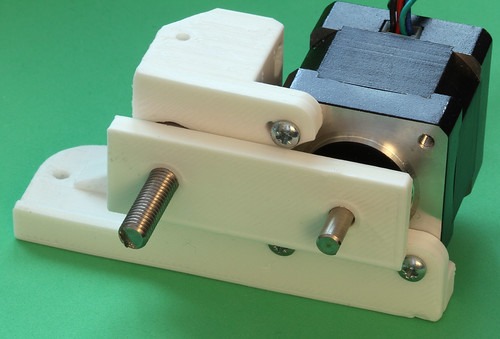

A fixture is a support tool that locates and secures the workpiece in a stable position. The solid component of a fixture is where the part rests. This portion of the fixture is attached to the floor or machine body and is immovable so it can hold the part steady and not move when force is applied during the manufacturing process. Buttons or pins are used as locator devices to place the workpiece quickly and correctly each time. Clamps are then used to secure the part in one position. This enables the orientation of the part to controlled as well. Fixtures aid in a faster production process because the placement and securing of each part is reliable every time.

Benefits to Manufacturing

The most efficient manufacturing processes are those that are mostly or fully automated because they produce parts quickly and accurately with very little room for human error from an operator. Jigs and fixtures are essential components needed to automate a production process. Specifically, the use of jigs and fixtures in a production does the following:

Ensures uniform part quality: Parts are set up and manufactured the same way each time, which makes them identical and far less likely to incur defects that come from manual placement.

Ensures uniform part quality: Parts are set up and manufactured the same way each time, which makes them identical and far less likely to incur defects that come from manual placement. - Simplifies the production process: By automating the locating, holding, and cutting of the workpiece, less skill is required to perform the operations. Unskilled workers are just as efficient as skilled workers.

- Provides faster transition: Parts are located and manufactured with no guesswork, so parts are completed faster while retaining accuracy.

- Reduces costs: A high level of control and repeatability is achieved, which translates to fewer instances of rework that would slow production and increase its cost. The necessity for some production steps to have multiple workers is also negated since these tools may replace one or more operators.

- Increases worker safety: Worker strain and concentration is mitigated because parts and cutting tools must no longer be held steady or guided manually.

Why You Should 3D Print Your Jigs & Fixtures

Jigs and fixtures are most commonly CNC machined on a multi-axis mill or injection molded. While both of these options can produce superb jigs and fixtures, they have several drawbacks that can make the design and production of your jigs and fixtures quite challenging. 3D printing, however, is an alternative route that can solve some of the more prominent problems with traditional manufacturing. These advantages of using 3D printing to create your jigs and fixtures are discussed in detail below.

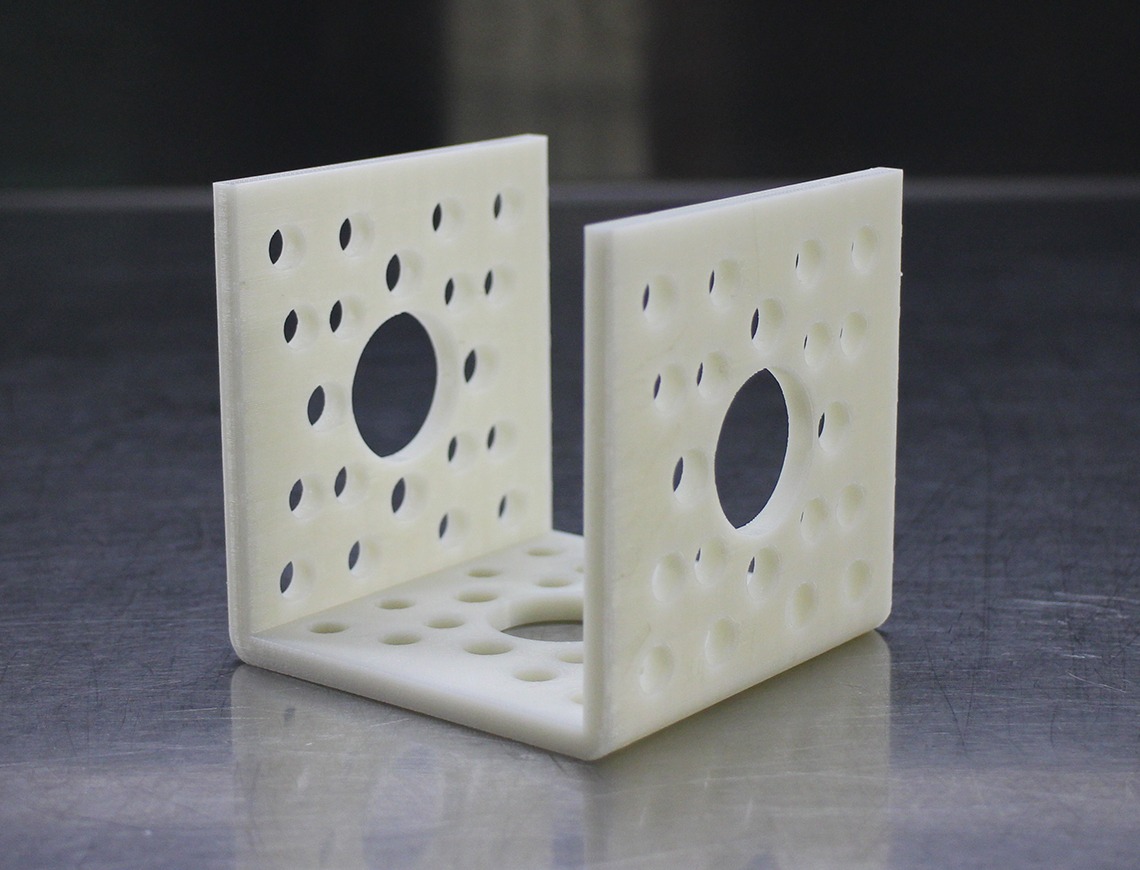

1. Fewer Geometrical Restrictions

Traditional manufacturing methods require that parts be able to be either machined or ejected from a mold. As such, engineers may spend much of their time simply trying to make sure the jig or fixture design meets the geometrical requirements of the mill or mold.  With 3D printing, however, an additive manufacturing process of building a part in layers is used. This process makes it easy to create parts with complex geometry, including assemblies. As such, rather than forcing a design idea to fit within the constraints of traditional manufacturing, engineers can devote more of their time to designing jigs and fixtures that work exactly as you intend. This can help speed up the design process as well.

With 3D printing, however, an additive manufacturing process of building a part in layers is used. This process makes it easy to create parts with complex geometry, including assemblies. As such, rather than forcing a design idea to fit within the constraints of traditional manufacturing, engineers can devote more of their time to designing jigs and fixtures that work exactly as you intend. This can help speed up the design process as well.

2. Sturdy & Lightweight

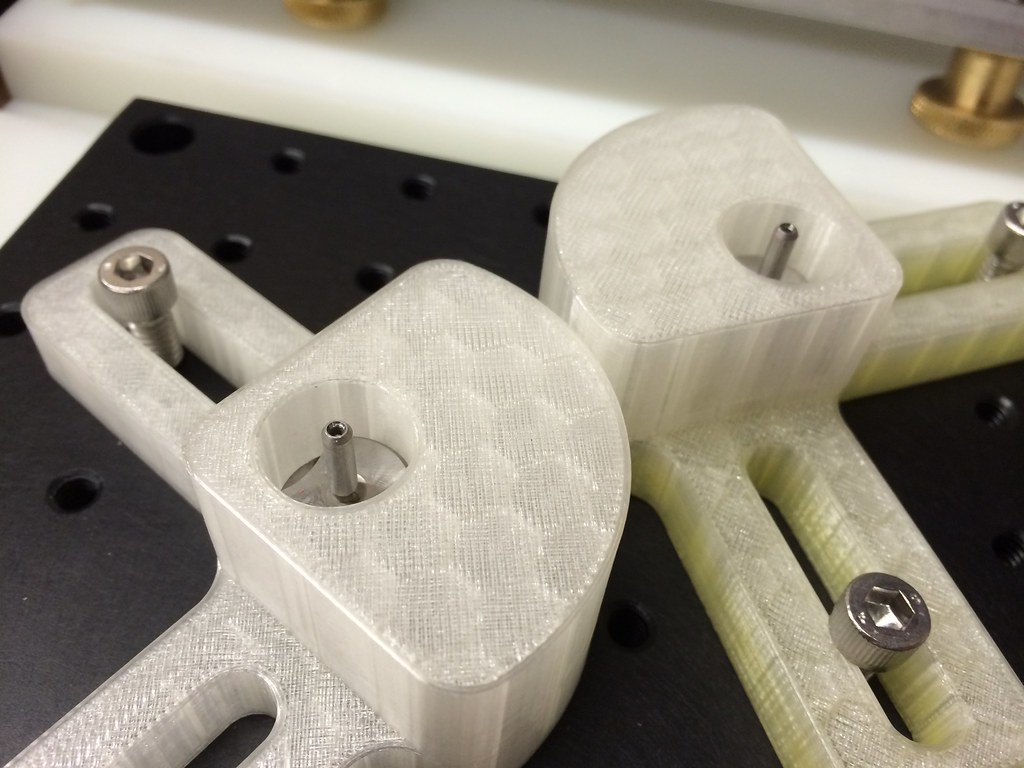

Jigs and fixtures are most commonly made from metal, and while DMLS 3D printing is a viable option for complex metal tools, plastics can serve as a smarter option. Contrary to popular thought, making a jig or fixture from plastic will often not compromise the production process. Rather, multiple high-performance industrial plastics can offer similar durability as some metals while making the jig or fixture lighter weight. This helps reduce worker fatigue as any manual operations with the jigs and fixtures may be easier to accomplish.

while making the jig or fixture lighter weight. This helps reduce worker fatigue as any manual operations with the jigs and fixtures may be easier to accomplish.

3. Faster Lead Time

Unlike traditional manufacturing methods, 3D printing does not require any tooling to create parts. Layers are made directly on a flat build tray, so the setup is minimal and you don’t have to wait weeks for molds or other tooling to be cut. With 3D printing, you can go directly from a finished design file to a jig/fixture in hand in a matter of hours or days depending on the complexity and size of the part. This is particularly helpful when trying to prototype iterations of your design. Furthermore, because a jig or fixture can be produced so quickly, there is no need to order in bulk. You can order in small batches or one at a time on an as-needed basis.

4. Lower Cost

3D printing is much more affordable because there are no upfront tooling expenses that are typical of injection molding and machining. Because of this, the cost per jig/fixture is lowered.  Additionally, while CNC machining is the preferred method for manufacturing jigs and fixtures, it is a subtractive manufacturing process. This means it carves away material from a blank to create parts, and this equates to a lot of wasted material. 3D printing, on the other hand, uses only the exact amount of material you need for each part. This saves on overall material cost.

Additionally, while CNC machining is the preferred method for manufacturing jigs and fixtures, it is a subtractive manufacturing process. This means it carves away material from a blank to create parts, and this equates to a lot of wasted material. 3D printing, on the other hand, uses only the exact amount of material you need for each part. This saves on overall material cost.

3D Printing at 3 Space

Here at 3 Space, we’ve completed many notable projects over the years, including scanning and manufacturing fixtures for Whirlpool. For your jigs and fixtures, we can 3D print a ready design file or help you develop a design from existing CAD of your part that needs a jig/fixture. If you don’t have this CAD, it’s no problem! We can use our in-house 3D scanning lab to reverse engineer CAD of your part. For more information, contact us today. We look forward to working with you!