Common Defects in Injection Molding

Injection molding is a method of mass production manufacturing and is not without its faults. Defects can be minor surface marks or major areas of

Injection molding is a method of mass production manufacturing and is not without its faults. Defects can be minor surface marks or major areas of

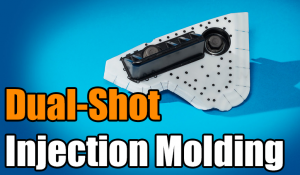

Dual-shot plastic injection molding, sometimes simply referred to as overmolding, is an efficient manufacturing process that allows you to produce your multi-material and/or multi-color

Injection molds may be classified by multiple different categories based on their features, such as runner system, plate amount, and part capacity. These classifications

When choosing your tooling material, the expected volume of your production will have a great bearing on what material will best suit your needs.

What is Rubber Injection Molding? Rubber injection molding is similar to rigid plastic injection molding, except that the materials being used have flexibility and

Both thermoforming and injection molding are widely used plastic manufacturing methods. While both technologies require molds, they differ in many areas, including process, part

The cost of injection molding depends on multiple factors, including part complexity, tooling, materials, labor, quantity, and production location. You can expect to spend

This post is part of our Injection Molding Design Guide series. Press-fit connections can be tricky to manufacture via injection molding if you’ve never

This post is part of our Injection Molding Design Guide series. With plastic injection molding, it is important to design for manufacturability. To do this,

This post is part of our Injection Molding Design Guide series. Ribs can be instrumental to your part’s structural success. If used correctly, you