Developing a concept into a product may seem daunting, especially since some projects can take weeks, months, or even years to complete depending on their scope. To make it less overwhelming, we’ve broken down the product development process into four key stages. This general model can be adapted to fit your specific project needs

.

1. Discovery & Idea Generation

In product development, the primary goal is to create a product that fills a gap in the market and meets the needs or wants of the consumer. As such, the initial stage of the development process requires that you first determine what the market lacks and think of creative solutions to fix it.

Finding the gap in the market that you wish to fill can take some time and can be approached in different ways. For example, the entrepreneur may find inspiration for a product by noticing unmet needs in their everyday life or those of friends and family. On the other hand, large established companies who are looking for ways to expand their product line or improve on an existing product may discover the same idea through market research, including conducting surveys with their target customers, observing competitors, exploring internet search trends, and more.

Finding the gap in the market that you wish to fill can take some time and can be approached in different ways. For example, the entrepreneur may find inspiration for a product by noticing unmet needs in their everyday life or those of friends and family. On the other hand, large established companies who are looking for ways to expand their product line or improve on an existing product may discover the same idea through market research, including conducting surveys with their target customers, observing competitors, exploring internet search trends, and more.

Once the market gap is pinpointed, it is time to brainstorm potential solutions. This should be done by taking note of each idea without judgement or worry of cost or other manufacturing details. Rather, the point is to explore a multitude of creative avenues that will be sorted through later. When you feel satisfied with your list, you can move on to the next step.

2. Screening & Concept Development

At this point, you might feel overwhelmed by your list of ideas, or you might feel confident that one or several stand out and are the way to go. Whatever the case, it is important to use a careful screening process to narrow down your ideas to only one that you take forward.

To weed out non-viable ideas, it is recommended to first make a list of requirements that you wish for your final idea to meet. This may include anything from how well the idea satisfies the needs of the customer to whether it fits your brand image and more. A crucial requirement will likely be that your idea needs to fit a certain budget as well. Calculating the risk vs. reward can be done several ways, but is usually boiled down to a SWOT analysis, which assesses the strengths, weaknesses, opportunities, and threats to a potential product. This analysis is a high priority in this stage as it may bring attention to possible problems, such as competitor patents or technological advancements that could render your future product obsolete. Finally, it is also a good plan to run some of your viable ideas past co-workers and focus groups if possible to gauge response and interest.

To weed out non-viable ideas, it is recommended to first make a list of requirements that you wish for your final idea to meet. This may include anything from how well the idea satisfies the needs of the customer to whether it fits your brand image and more. A crucial requirement will likely be that your idea needs to fit a certain budget as well. Calculating the risk vs. reward can be done several ways, but is usually boiled down to a SWOT analysis, which assesses the strengths, weaknesses, opportunities, and threats to a potential product. This analysis is a high priority in this stage as it may bring attention to possible problems, such as competitor patents or technological advancements that could render your future product obsolete. Finally, it is also a good plan to run some of your viable ideas past co-workers and focus groups if possible to gauge response and interest.

Concept plans for your chosen product should be finalized as much as possible during this stage so you can confidently move on to designing.

3. Design & Manufacturing

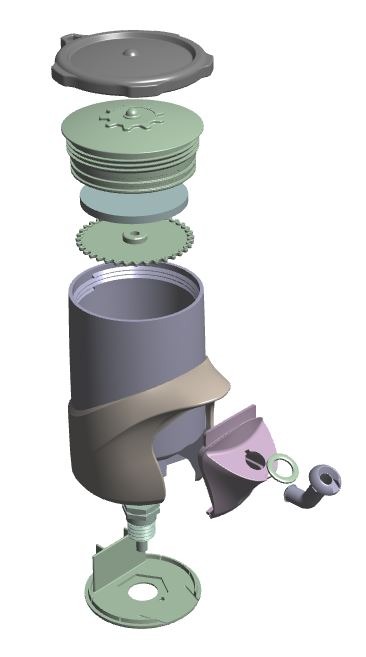

The finalized concept moves into the design stage where the specs of the product are determined, tested, and altered as needed. This involves close consideration of every detail down to the smallest measurement to ensure that the functionality, aesthetic, and manufacturability are on par with the previously laid out feature requirements and budget. The design stage can be broken down into several phases:

Initial Design: A design is drawn up to show how the product should look and feel, what its measurements are, what material is to be used, and more.

Initial Design: A design is drawn up to show how the product should look and feel, what its measurements are, what material is to be used, and more.- Prototype & Test: A prototype is made and tested for proper functionality and aesthetics. Testing may occur with a sample group of the target audience as well. Rapid prototyping with 3D printing is recommended so that your design stage can move much faster.

- Revise: Based on feedback from the prototype, alterations are made to the design. With each revised iteration, a new prototype should be made for further testing until the design is perfected.

- Samples from Manufacturer: Once the design is finalized, it is sent to your chosen manufacturer so samples can be made and you can check the quality of the manufacturing process. Some changes may have to be made after receiving samples. For example, with traditional injection molding, you might want to change the texture of the mold or where the parting lines are. It is best to perform a FAI on each sample batch to perfect the form, fit, and function of your final product before large-scale production begins.

- Manufacture: At this point, your product should be finalized and ready to go into production.

The design process is fluid, and you may find yourself going back and forth between some of these phases multiple times. Keep in mind that reworking a design is perfectly normal and should not be rushed.

4. Marketing & Launch

Leading up to the launch of your product, marketing is essential. You want to let people know it exists and show them why it’s the best option on the market. Depending when you set your  launch day, you may choose to begin your marketing strategies earlier when the product’s design is mostly done. By doing so, you give your marketing campaign more time to garner attention and build interest.

launch day, you may choose to begin your marketing strategies earlier when the product’s design is mostly done. By doing so, you give your marketing campaign more time to garner attention and build interest.

Product Development at 3 Space

Here at 3 Space, we offer high-quality, thorough product development services to help your idea become a reality. With our team of expert engineers and in-house 3D printing, you’ll get top-of-the-line service. For more information or to request a quote, contact us today.