Injection molds may be classified by multiple different categories based on their features, such as runner system, plate amount, and part capacity. These classifications are not exclusive, but rather every mold will fit a label within each category. For example, you may have a mold that consists of a cold runner system, three plates, and has multiple cavities. Understanding what each of these categories means for your molding process will help prepare you to select the right type of mold for your part.

The Importance of the Right Mold

Choosing the correct mold type for your production is crucial because the type of mold will directly impact product quality, production speed, and, as a result, overall costs. While the type of mold you choose will also influence upfront cost of the mold, it is important to consider that the cost will change if more complexity or stronger tool material is required, such as side actions or pick-outs, steel in place of aluminum, or the mold is to be used for overmolding or insert molding.

There are multiple different ways to classify a mold based on different attributes of the mold. Below, we’ll discuss the primary three categories:

Type by Runner

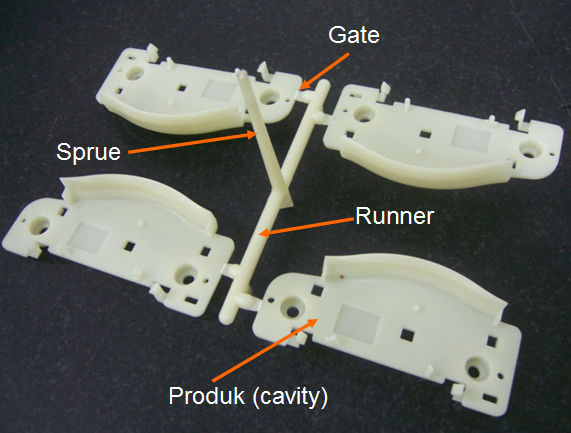

The first category of types of injection molds classifies a mold by its type of runner system. A runner system is a series of channels, including a gate, sprue, and runners, that direct the molten plastic material from the machine’s nozzle to the desired areas of the mold’s cavity.

Hot Runner

A hot runner system involves runners that are either internally or externally heated by rods, coils, or other heating elements. Because it must be heated while the mold is cooled, this type of runner system is encased within a stationary manifold plate. Since the runners are held permanently within this plate, they will not eject with the part, so the molded part comes out clean and devoid of extra plastic waste attached. This reduces waste, and there are no added production steps to remove the runners and recycle them as there are with cold runner systems, meaning production is allowed to move much more quickly. This type of mold is typically used for large volume productions with multiple mold cavities because it is expensive to heat and requires more maintenance that its cold runner sibling. Additionally, because the runners are hidden, it can be difficult to ensure the runners are clean and clear of leftover plastic from previous productions.  This can be a disadvantage especially if you are changing material or color between batches. Finally, internally heated hot runner systems can cause problems, such as sticking, when dealing with thermal sensitive materials.

This can be a disadvantage especially if you are changing material or color between batches. Finally, internally heated hot runner systems can cause problems, such as sticking, when dealing with thermal sensitive materials.

Cold Runner

A cold runner system uses unheated runners to deliver melted plastic into the mold cavity. However, as opposed to hot runners, a cold runner system is exposed because it is cut into the mold itself. This means that a new runner system is made, solidified, and ejected with each mold cycle. Depending on whether a two-plate or three-plate mold is used, the runner system and the molded part may be conjoined or separated when the part is ejected. This type of runner system does create a lot of waste each cycle, but it is simple to grind up the discarded runners to recycle and reuse them. Unfortunately, this adds steps to your production process, so production may be lengthened by this. It is important to note that cold runner systems are easier to clean and maintain for simple color and material changing. Additionally, design changes are easier to incorporate because runner and gate positions can be changed faster than those of a hot runner system. Where internally heated hot runners may struggle with some materials, cold runners work with a wider selection of materials.

Type By Plate

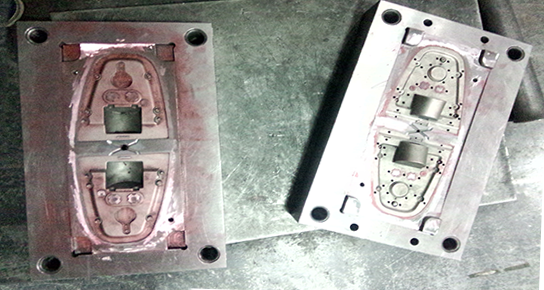

Another category by which injection molds may be sorted is the amount or configuration of their plates. A mold is made up of plates that have the part’s negative cut into them. When pressed together in the injection molding machine, these plates form the full mold cavity for proper production of the part.

Two-Plate

Two-Plate

A two-plate mold is the most common type used for injection molding as it is the least expensive to manufacture. It has only one parting line where the two halves, the core plate and the cavity plate, meet. Though both types of runner systems are used in two-plate molds, a cold runner system will be ejected still attached to the part. This adds more production steps and labor costs because each runner system will have to be manually removed and recycled.

Three-Plate

A three-plate mold has an additional plate that makes the mold have two parting lines instead of one. This added plate, or stripper plate, is positioned between the core and cavity plates and serves the purpose of automatically separating the cold runner system from the molded part upon ejection. This allows for a speedier production as no manual labor is needed to break off the runner system and send it to recycling. As expected, adding this plate will increase the overall tooling cost for your mold as it must be cut to match up with the other two plates to ensure proper separation and ejection. Keep in mind that since this third plate is only needed to detach the runner system, a hot runner system will never require a three-plate mold.

Stacked

A stacked mold consists of multiple parallel levels of mold plates. These two, three, or even four levels are used to make production more efficient. This is accomplished because a stacked mold requires less clamp tonnage during a cycle than a single level mold with an equal amount of cavities. While this lowers operating costs, the upfront cost of this type of mold is steep because it takes longer to build. This mold type can even be made to accommodate multiple materials at once.

Type by Volume

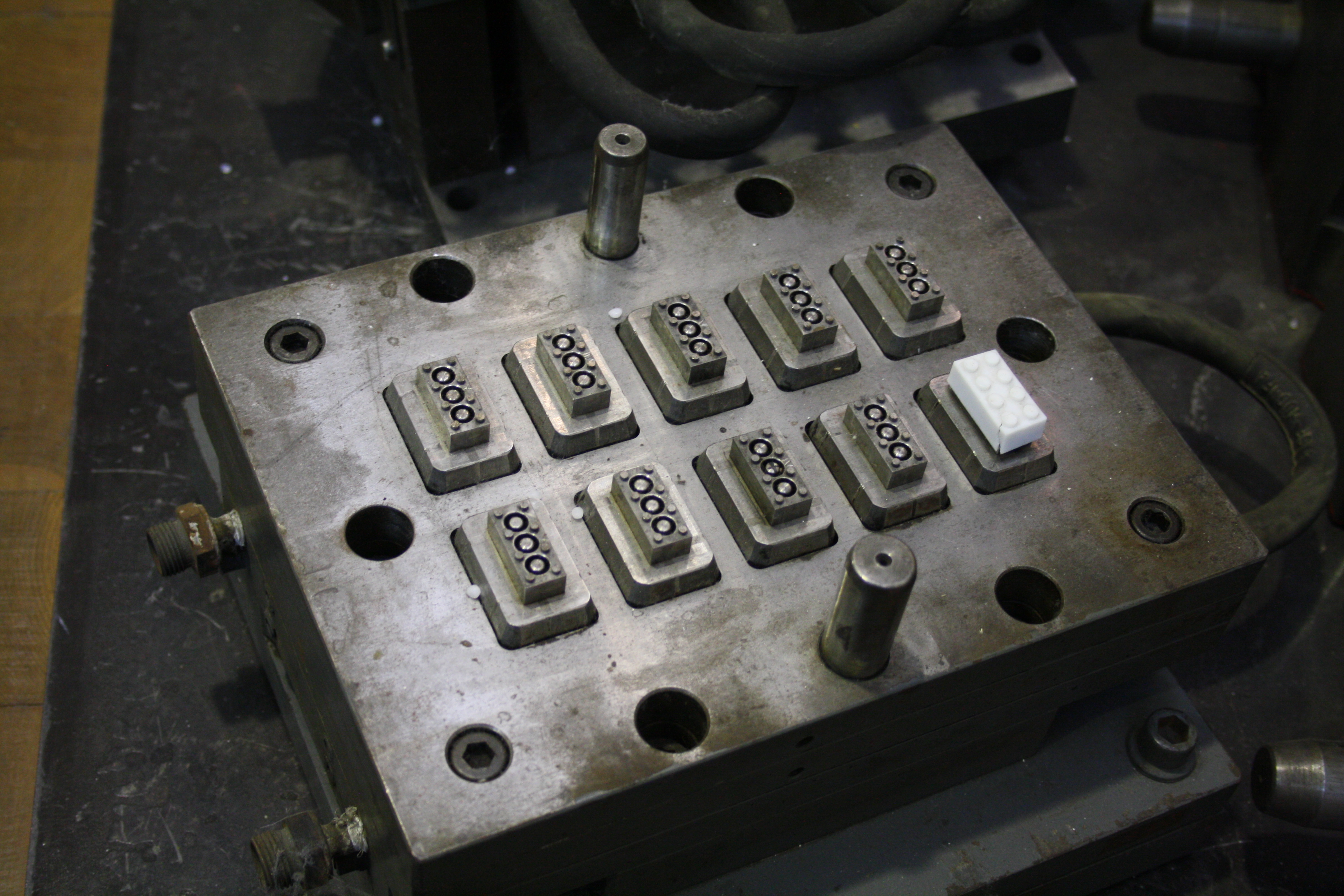

The final category of injection mold types is based on the volume the mold can produce each cycle. The number of cavities in a mold determines the quantity produced every cycle and greatly dictates the speed of production.

Single Cavity

A single cavity mold produces only one part per cycle. While this may prove to be the slowest production mold type compared to the ones below, this use of a single cavity allows the mold to be made much cheaper than other options. This relative lower cost also makes it so that smaller volume productions are more affordable.

Multi-Cavity

Multi-Cavity

A multi-cavity mold is designed to make multiple identical parts per cycle. This type of mold is more expensive because it takes longer to cut with each cavity that is added. Large volume productions are typically accomplished with this type of mold because each mold cycle can be made to produce much more than a single cavity mold, aiding in production speed.

Family

A family mold also consists of multiple cavities, but it is used to make multiple different parts per cycle. For example, a family mold may be made to produce two left and two right iterations of a part, whereas a simple multi-cavity mold would only produce the left iteration each cycle. While this type of mold is still expensive due to the time it takes to cut the additional cavities, it may actually help reduce overall tooling costs because one family mold could be used for many different parts rather than a regular multi-cavity mold for each different part. This also allows a lot of time and machinery operation costs to be saved. It is important to note, however, that a family mold can only be used for parts that are to be made of the same material and color. Parts requiring different materials or color variations must be made in separate molds or batches.

3D Printed Molds

While not a common selection for injection molding, 3D printed molds offer another option for your production process. Typical plastic injection molding tooling takes weeks to cut, which may potentially set back production while you wait. However, you can use a 3D printed mold as bridge tooling during this time because a mold made this way can be produced in as little as 48 hours. It is crucial to understand that these molds are made of plastic and, therefore, can only handle roughly 100 mold cycles before they begin to deform. Additionally, while speed may be a huge advantage, 3D printed molds are very expensive. They should only be used if you need parts immediately or in small batches.

Injection Molding at 3 Space

Here at 3 Space, we offer multiple manufacturing services, including both injection molding and 3D printing. If you are unsure which mold type is most viable for your production plans, don’t hesitate to contact us. Our expert engineers are happy to guide you through the selection process so your part can be made exactly how you envisioned.