3D printing a part can take anywhere from 30 minutes to 7 days or more. There are a several factors that dictate how long it takes to 3d print a part. These include the overall size and geometry of the part as well as the 3D printing technology being used. The larger the part or the more complex the geometry, longer it will take to 3D print.

However, we can offer a quick and dirty answer by providing a few reference points. The parts above represent the typical size and shape of parts that we 3D print here at 3 Space and should provide you with a general idea of how long it might take to 3D print your own parts. Of course, this is just an estimation. Read on to learn more about the various factors that dictate build time for various 3D printers.

Part Size

Volume

Several factors dictate how long it takes to 3D print a part, but the volume of the part is usually the first indicator. As a general rule, the larger the part the more time it will take to print. We’ve seen small parts (about 1 cubic inch) take as little as 5 minutes to 3D print, while very large parts (100+ cubic inches) can take upwards of 200 hours.

Footprint (XY)

The part’s footprint, or the area it occupies on the build surface, plays a role in determining the time to 3D print. The larger the footprint, the farther the print head has to travel from its home position to complete each layer.

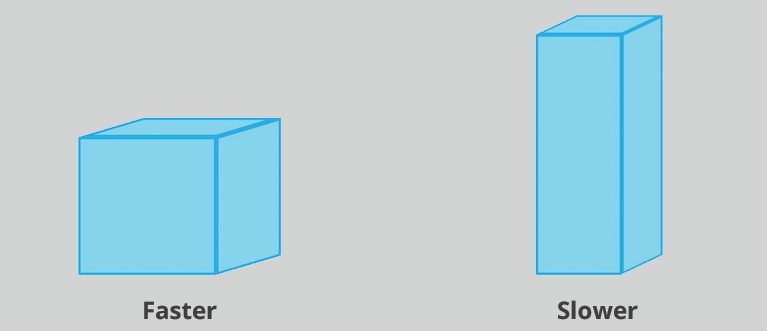

Height (Z)

While the overall size and footprint important, the build height of a part is probably the single most important dimension in determining how long it will take to 3D print. A part that is 4x4x8” will typically take longer to 3D print than a part that is 5x5x5” even though they are roughly the same volume. That’s because the taller part will have more layers and the print head will therefore have to make more passes to create them. Barring wildly different geometry, each layer should take roughly the same amount of time to print.

Part Geometry

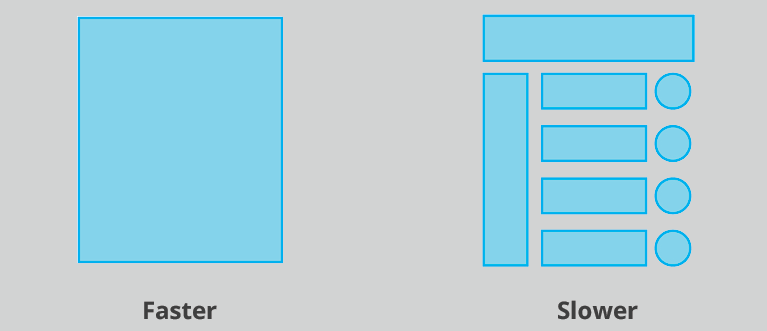

The complexity of a part’s geometry is another important factor in determining how long it takes to 3D print. The more complex the part is, the more complex each layer will be. And the more complex the layers are, the longer it will take for the print head to replicate them.

A part with many small features will have layers that look like a group of small islands, while a simple cube or sphere will have one large island. The print head will have to draw the boundary each island and then fill it in, so more islands means more time. However, that the degree to which part geometry affects build time is highly dependent on the 3D printing technology being used.

3D Printing Technology

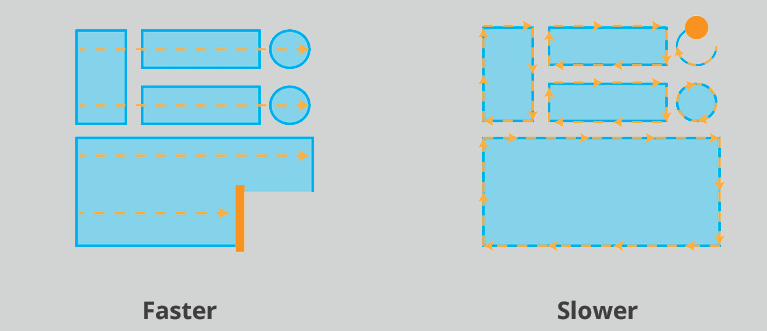

At this point there are about a dozen different 3D printing technologies and they each create parts using their own unique processes. FDM melts plastic like a hot-glue gun, SLS uses lasers, PolyJet and stereolithography use UV light to solidfy liquid photopolymers and so on. But when discussing how long it takes to 3D print a part, the most important factor is the configuration of the print head. We can broadly divide print head configurations into two categories: paint brush and paint roller.

Paint Brush

These are 3D printing technologies where layers are created the same way that you would paint them on canvas with a brush. The print extrudes material (or fires a laser, as the case may be) from a single point as it moves all over the build tray, drawing out each island in the layer. These technologies include FDM, selective laser sintering and stereolithography.

Paint Roller

For these technologies the print head evenly passes back and forth across the entire build tray, the way you might paint a wall with a paint roller. Material is extruded from an array of points on the print head, rather than just a single pinpoint. These include PolyJet, MultiJet, and ColorJet 3D printers.

The result of this difference is that “paint brush” printers typically take longer to 3D print than “paint roller” printers. While the FDM print head has to go spiraling all around the build chamber, drawing out and filling in each shape in the layer, the PolyJet print head makes a few quick and even passes across the entire bed, regardless of the geometry it’s printing.

Layer Height

We’ve discusses how important the height of the overall part is, but the height of the individual layers also determines how long 3D printing takes. Our FDM machines, for example, can build parts with layer heights of 0.005”, 0.007”, 0.010” or 0.013”. Using different layer heights allows you to prioritize speed or detail, depending on your part’s requirements.

Shorter layer typically mean smaller features, higher detail and a smoother surface finish. But shorter layers also mean that there will be more layers and therefore a longer build time. For example, FDM parts with 0.005” layers can take up to 5-10 times longer to 3D print as parts with 0.013” layers.

Quantity

All of the above factors that determine how long 3d printing takes are compounded when you are printing more than one copy of the same object. You will always reduce your per-part time when printing multiple copies, but the more factors you already have in your favor, the more time you will save.

For example, it takes about an hour to 3D print one copy of a 1” cube on PolyJet, but it only takes two hours to print 25 copies. Meanwhile, printing two copies of a large FDM part with short layers will generally take about twice as long as printing one.

Post-processing

Post-processing activities include support removal processes to ultimately clean, rinse, and/or dry 3D printed parts. Each technology requires different methods of post-processing. Of course, average times vary depending on factors such as size and geometry of the parts. A small part may only take 20 minutes to clean, while a larger part could take several hours. The most important part of the post-processing activities is to be careful not to break or damage the parts as they can often be fragile depending on their design.

3D Printing at 3 Space

At 3 Space we offer a variety of 3D printing technologies and dozens of materials. Whether you need rapid prototyping or end-use parts, 3D printing is almost always time-sensitive. We strive to maintain short lead times for all of our 3D printing services. Click here to learn more about our services.