There are several variables that contribute to the cost of 3D printing, including print time, the type of material used, and post-processing labor. Many 3D printing service companies will bill based on an hourly rate, while others may bill according to cubic inches or a combination of both.

For sake of clarity, this article will discuss 3D printing cost factors as they pertain to the industrial level. Below, we will discuss how the print time, type of material, and post-processing labor factor in to the cost of a 3D printed part.

Print Time

Many factors influence the time it takes to complete a 3D print. These factors primarily stem from the part’s design specifications, including its complexity, overall size, layer height, and resolution. Below, we’ll discuss what these elements are and how they can affect the build time:

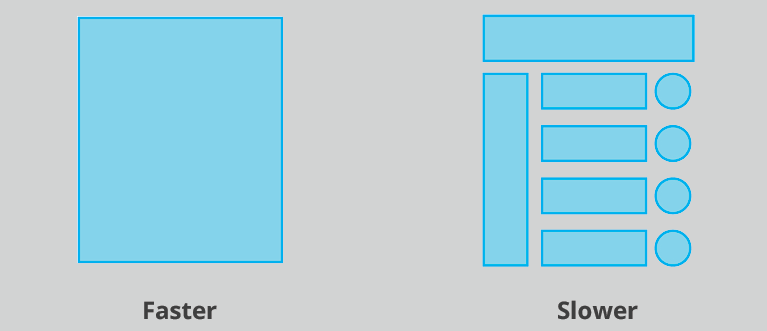

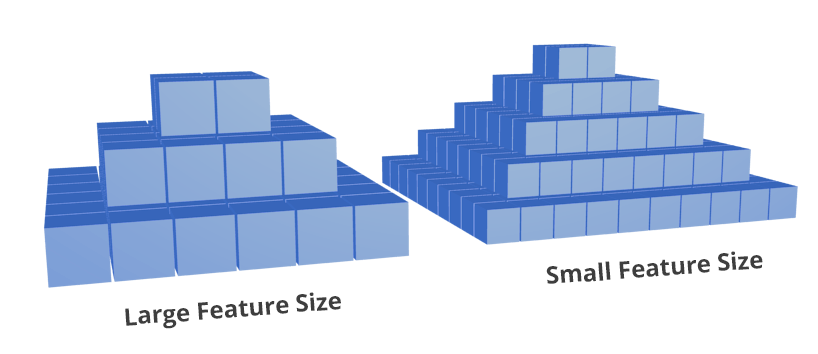

Complexity

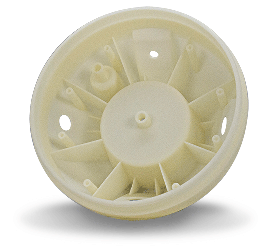

The complexity of a part’s geometry largely determines the shape of the cross-sectional layers that the 3D printer uses to create the part. If the layers are simple, such as single-island layers for a cube, the printer can complete them quickly. However, where there are small features, the printer will have to stop, move to the next location where the material continues, and start again. This creates islands that the printer must form boundaries for before continuing. Furthermore, some 3D printing technologies utilize support material for complex designs, and creating a layer made up of both model material and support material will take longer than a layer composed of only model material.

The complexity of a part’s geometry largely determines the shape of the cross-sectional layers that the 3D printer uses to create the part. If the layers are simple, such as single-island layers for a cube, the printer can complete them quickly. However, where there are small features, the printer will have to stop, move to the next location where the material continues, and start again. This creates islands that the printer must form boundaries for before continuing. Furthermore, some 3D printing technologies utilize support material for complex designs, and creating a layer made up of both model material and support material will take longer than a layer composed of only model material.

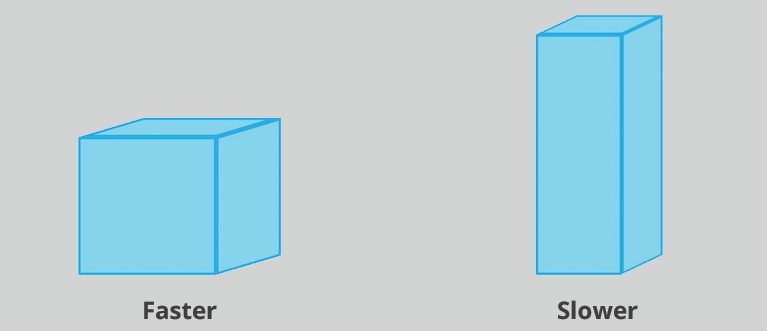

Overall Size

A part’s size can shorten or extend the print time drastically. Every 3D printer has a point of origin where the print head nozzle, laser, or light beam starts each layer. A large part requires this print head to move a farther distance from its starting point and, thus, the layer takes longer to complete than a part with a smaller footprint. Tall parts are also often time consuming because they require more layers to build them. For small parts, however, the printer can move through layer creation rapidly because the print head requires less movement from its starting position.

A part’s size can shorten or extend the print time drastically. Every 3D printer has a point of origin where the print head nozzle, laser, or light beam starts each layer. A large part requires this print head to move a farther distance from its starting point and, thus, the layer takes longer to complete than a part with a smaller footprint. Tall parts are also often time consuming because they require more layers to build them. For small parts, however, the printer can move through layer creation rapidly because the print head requires less movement from its starting position.

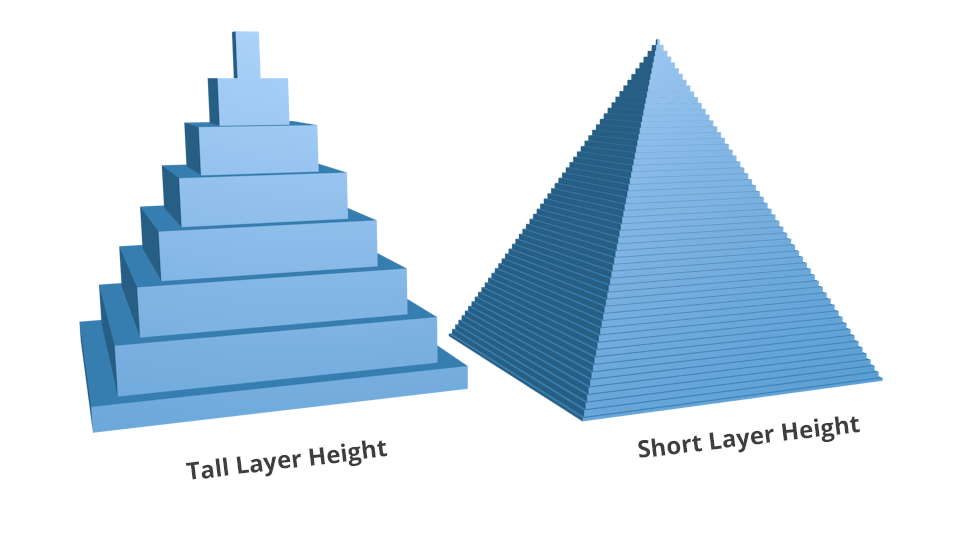

Z Height

In addition to overall size, your chosen Z height, or layer height, is an indicator of how long it will take to print your part. Every 3D printer will produce your part’s layers with a specified height so that all the layers are uniform in thickness. Thicker layers will allow the part to be printed more quickly than it would with thinner layers. However, thinner layers may be desired for a higher quality appearance in the part.

In addition to overall size, your chosen Z height, or layer height, is an indicator of how long it will take to print your part. Every 3D printer will produce your part’s layers with a specified height so that all the layers are uniform in thickness. Thicker layers will allow the part to be printed more quickly than it would with thinner layers. However, thinner layers may be desired for a higher quality appearance in the part.

Resolution

A part’s quality, which is affected by the 3D printer’s resolution, is also worth considering when calculating print time. Resolution is primarily determined by the layer height used by the 3D printer, which can be adjusted for a finer resolution as desired. It is important to note, however, that a finer resolution will mean more layers, which means more time to print your part.

A part’s quality, which is affected by the 3D printer’s resolution, is also worth considering when calculating print time. Resolution is primarily determined by the layer height used by the 3D printer, which can be adjusted for a finer resolution as desired. It is important to note, however, that a finer resolution will mean more layers, which means more time to print your part.

Furthermore, you may note that if you are planning to produce your part with a Fused Deposition Modelling (FDM) 3D printer you will also need to account for infill influencing your part’s build time. FDM printers come with automatic settings to control your part’s infill, and it may be crucial to determine which infill will best suit your part’s application requirements while still accounting for time lost or gained from the selection.

Material

In addition to how much material you are using, your cost will also depend on what type of material you select. The majority of 3D printing materials can be categorized as one of four types: thermoplastics, photopolymers, polymers, and metals. Cost will fluctuate based on the specific material and the manufacturer, but for the most part, the estimates below are what you can expect each type of material to cost.

For these cost estimates, we are using numbers for raw materials only. A 3D printing service company will typically mark up costs 2-3 times these amounts, which you should factor into your total cost if producing via that route.

Thermoplastics

Thermoplastics

Thermoplastics are rigid, widely used materials that must be melted prior to extrusion. They are used in FDM 3D printers, which is the most common type of 3D printing. Because they are so commonly used, the cost of these materials is one of the lowest available. The average cost for thermoplastic model filament will range from $3.50 to $7.50 per cubic inch. Because FDM printers require the use of support material, it is necessary to include the cost of support material filament, which will cost around the same as model filament. However, only a fraction of the part’s overall volume will be comprised of this support material.

Photopolymers

Photopolymers

Photopolymers are liquid resin thermosets that must be cured by UV light. They are used in PolyJet, MultiJet, and Stereolithography (SLA) 3D printers. Photopolymer model material will run $0.32 to $0.36 per gram, and support material may be between $0.11 and $0.21 per gram. This cost is based on the fact that photopolymer resins are made for these specific 3D printing processes and are not as widely used as thermoplastics. Keep in mind that SLA uses the model material for support structures and, therefore, will not need any additional support material to be purchased.

Polymers

Polymers are similar to thermoplastics, but they exist in a fine powdered state and are sintered together via a laser with Selective Laser Sintering (SLS). This powdered material is very cheap, costing around $0.10 per gram. Due to the nature of the SLS process supporting the parts with a type of powder “cake” of unsintered material, other support material is not needed.

Metals

Metals

Metal 3D printing materials are essentially the same as polymers in that they exist in a powdered form and are melted together via a laser with Direct Metal Laser Sintering (DMLS). However, metal material is highly expensive, reaching around $0.60 per gram. Additionally, even though the DMLS printing process forms a powder cake like that of SLS, support structures are needed because metal is more dense than plastic.

Post-Processing Labor

After a print is done, the part will still have to go through more steps to make it ready to use. Some of these steps, such as the removal of support material, washing, sandblasting, sanding, drying, and gluing, will be mandatory for some parts and will not cost any extra fee. However, most all add-on steps, such as priming, dyeing, painting, coating, and more, will require extra time and manual labor to complete the part, which will factor into and result in a higher total cost.

3D Printing at 3 Space

Here at 3 Space, we aim to provide quality 3D printing services at an affordable price. Our expert engineers are happy to help advise you in how to get the best bang for your buck. For a personalized quote, contact us today.