There are two approaches to creating CAD: parametric modeling and direct modeling. Both are useful for different aspects of the design process and can make your model creation much smoother. In this article, we’ll discuss the characteristics of both approaches, how they are made, and how the two compare to each other.

Parametric Modeling

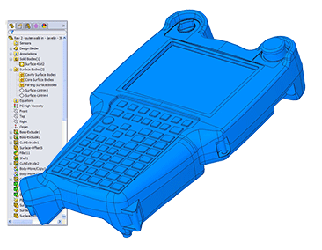

The parametric modeling method is a structured engineering process that is often referred to as history-based modeling. This is because it keeps a log of the model’s features, and as new features are added to the model, they are cataloged in this list, called a feature tree, making them easily accessible to edit. Each feature is made by manually inputting dimensions so that every measurement and angle is carefully controlled. The features are also controlled by parameters that have been defined by the engineer making the model. This enables the engineer to maintain design intent while creating and modifying the model because any modifications made will adhere to the set parameters that tell the model how to behave.

engineer to maintain design intent while creating and modifying the model because any modifications made will adhere to the set parameters that tell the model how to behave.

Advantages

- Structure – Every feature is controlled by dimensions, allowing for precise movements and modifications.

- Design intent – The parameters keep the model from straying from the original design intent. These algorithms instruct the features how to react to changes made in other parts of the model.

- Feature tree – The list that records each feature is easily accessible at all times and keeps a linear step-by-step creation log.

- Automated changes – Whenever a feature’s dimensions are modified, the change is reflected in the visual model immediately. Identical features can also be edited simultaneously.

Disadvantages

- Concept design – When brainstorming options for a design, making many model iterations via parametric modeling is often tedious and stifles the creative process.

- Careful planning – Each time a change is made to the model, the program updates the model by resolving each feature according to the linear order of the feature tree. The features are connected as they build upon each other in the list. If the engineer is not

careful, certain changes earlier in the feature tree may break the model as it tries to resolve features further down the tree. This can also make late-stage design changes difficult.

careful, certain changes earlier in the feature tree may break the model as it tries to resolve features further down the tree. This can also make late-stage design changes difficult. - File size – As more features are added, the list in the feature tree grows longer. This can take extra time and power for the computer to resolve the model.

- Model sharing – Sharing the model as suite-specific CAD is difficult due to the multitude of CAD programs on the market. It is easier to convert the file to generic CAD to share it between computers, but doing so erases the feature tree from the file and can make further editing more difficult.

Best Applications

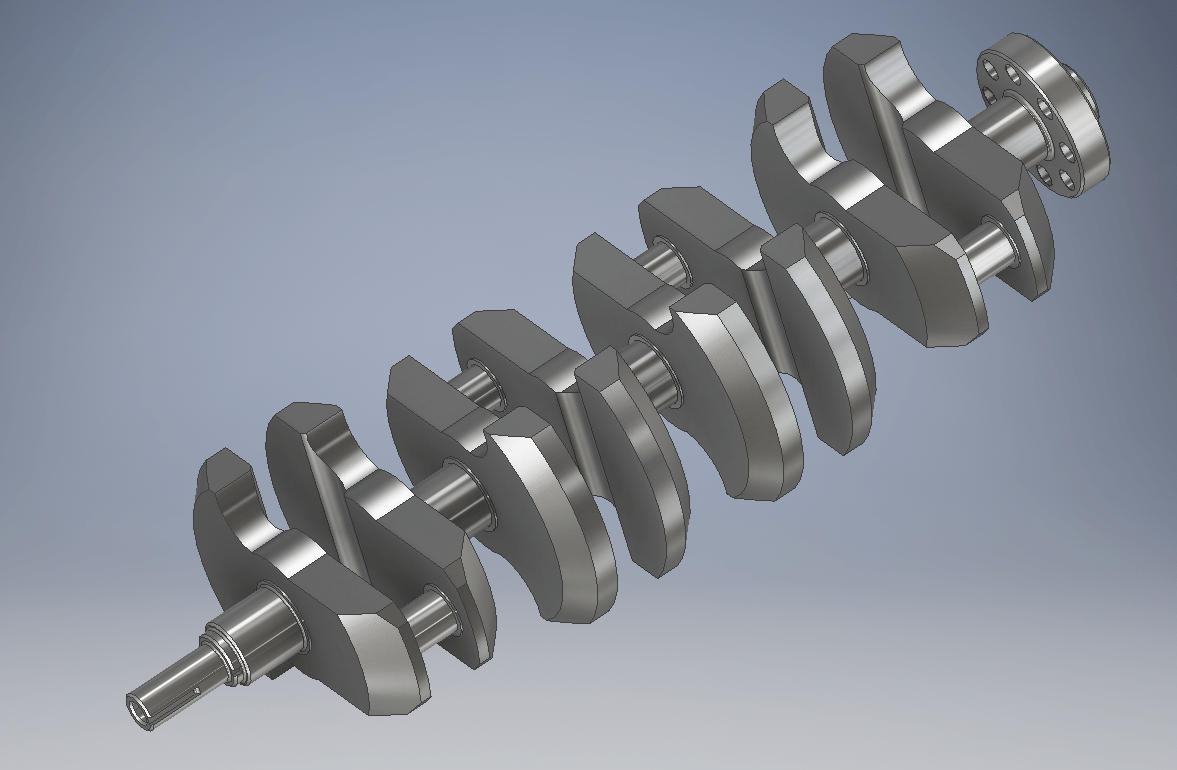

Parametric modeling is best used for tasks where exact dimensions must be created or met in order for production to continue. This is often in the engineering phase of production once the concept design of the part has been determined. It is also useful when a detailed log of features is needed, such as for parts that require frequent updating or belong to a family of products that must share some similarities.

Direct Modeling

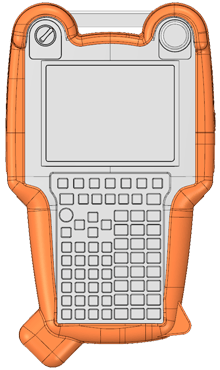

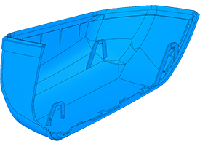

Direct modeling is a method that boasts flexibility and freedom. These characteristics stem from the fact that direct modeling is a history-free process, meaning that it does not keep any log of features or edits like parametric modeling does. No parameters are defined, so features are not tied to one another. Rather, the face of any given geometrical piece of the model can be pulled, pushed, or otherwise manipulated directly into the place the designer desires. This type of model may be compared to how a sculptor works with modeling clay. Design intent is defined as the piece progresses.

pulled, pushed, or otherwise manipulated directly into the place the designer desires. This type of model may be compared to how a sculptor works with modeling clay. Design intent is defined as the piece progresses.

Advantages

- Flexibility & Freedom – Since features are not connected to one another, changes can be made without worrying about breaking the model. This also allows for radical changes to be made at any point of the process.

- Speed – Making direct edits rather than inputting individual dimensions helps speed the process along. This can enable the designer to explore many design variations easily and rapidly.

- Versatility – Because no feature tree is kept with this modeling process, it can work directly with generic CAD models (STEP/IGES files).

Disadvantages

- Dimensions – Although dimensions may be shown when manipulating the geometry in a direct model, there is no history of these dimensions. This makes them harder to track and edit if you are looking for exact measurements instead of concept.

- Identical features – With parametric modeling, identical features, such as holes, can be modified simultaneously. However, direct modeling does not draw relationships between items, so if there are identical features like this, they must be edited individually.

Design intent – Because no parameters are used to define the design intent and make the model react accordingly to changes, it is easy to stray from the design intent.

Design intent – Because no parameters are used to define the design intent and make the model react accordingly to changes, it is easy to stray from the design intent.

Best Applications

The direct modeling approach is best used for tasks where flexibility and speed are desired, such as with concept design and rapid prototyping. It can also be helpful when designing a part that is a one-off design, will have a short life cycle, or is expected to go through many design iterations. The speed is more beneficial than parameter control in many of those instances and will, in turn, save resources spent on producing your model.

Which Approach is Better?

Which modeling method will work best for you largely depends on the intended purpose and current phase of your model. In general, however, a good blend of both is recommended because each will aid you in a different part of the modeling process. Both modeling types can lead to the same CAD result, which makes exchange between a parametric modeling program and a direct modeling program easy, although the feature tree from parametric modeling will be lost in this data exchange.

It is important to note that parametric and direct modeling typically exist in separate programs. While some modeling programs have begun to incorporate tools from both approaches, these programs are still in their infancy and do not offer the full benefits of either method.

It is important to note that parametric and direct modeling typically exist in separate programs. While some modeling programs have begun to incorporate tools from both approaches, these programs are still in their infancy and do not offer the full benefits of either method.

3D Modeling at 3 Space

Here at 3 Space, we work with CAD models every day for reverse engineering, product development, and more. Our team of expert engineers uses a blend of parametric and direct modeling to develop the perfect model for you. For more information or to request a quote, contact us today.