Deciphering which 3D printing technology is best for you can be difficult. Here, we’ve compiled a handy overview of the main six industrial 3D printing technologies found on the market, including FDM, PolyJet, MultiJet, SLA, SLS, and DMLS.

What is 3D Printing?

3D printing is a manufacturing option that allows parts to be made faster and with less waste than traditional manufacturing methods. As opposed to traditional manufacturing methods that use a subtractive manufacturing process, 3D printing uses an additive process. This works by taking a digital 3D model and slicing it into hundreds or thousands of cross-sectional layers. These layers are then recreated one-by-one on a build platform, building on top of one another until the 3D part is complete.

by taking a digital 3D model and slicing it into hundreds or thousands of cross-sectional layers. These layers are then recreated one-by-one on a build platform, building on top of one another until the 3D part is complete.

Due to the nature of the additive process, 3D printing can create parts within a matter of hours or days depending on the part size and geometry. As such, 3D printing is typically used for inexpensive, low-volume productions, such as is recommended for rapid prototyping and custom parts. Depending on the specific 3D printing technology, parts may be made from many materials, such as plastic, resin, metal, ceramic, glass, and more.

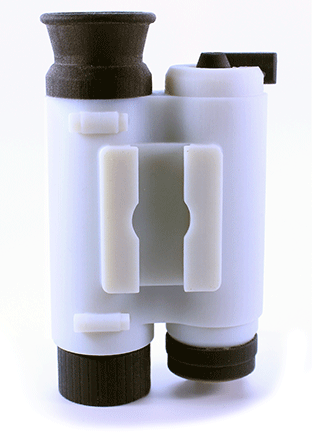

Fused Deposition Modeling (FDM)

Materials: In order to create parts, FDM uses thermoplastics, which are a category of polymers whose state can be changed by altering their temperature. When at room temperature, thermoplastics are solid, but when heated, they become soft and malleable. As such, they can be reformed over and over, making  them recyclable. Most often, the thermoplastics that are used in FDM printing are strong and rigid, but a few variations are available that offer flexibility like rubber and other common elastomers.

them recyclable. Most often, the thermoplastics that are used in FDM printing are strong and rigid, but a few variations are available that offer flexibility like rubber and other common elastomers.

Process: Thermoplastic filament is fed from a spool to the printer head where it is melted and extruded onto a build platform. Layers are built on top of each other, bonding and cooling as they are extruded. To prevent the temperature of the material dropping too fast and disrupting layer adhesion, the build platform is kept enclosed in a heated build chamber. Once all layers are completed, the part is removed from the built tray, stripped of its support structures, and put through additional post-processing steps for a clean finish.

Applications: Uses of FDM may include rapid prototyping, functional end-use parts, and high heat applications. It can commonly be found in the automotive, aerospace, education, and consumer goods industries.

PolyJet

Materials: PolyJet 3D printers utilize liquid resins that are cured by UV light. They are a type of thermoset material, which means that once they are cured, they can never return to a liquid form to be recycled. PolyJet is the only 3D printing technology that can print two model  materials at the same time. As such, different resins may be blended to achieve a wide variety of mechanical properties and shore hardnesses.

materials at the same time. As such, different resins may be blended to achieve a wide variety of mechanical properties and shore hardnesses.

Process: Resin is deposited on the build platform by a print head bearing hundreds of holes. The droplets are then cured by a UV light, which effectively solidifies them. Layers are added, and the composition of the resin makes it so they chemically bond to each other. Once all layers are complete, the part is removed from the build platform and cleaned of its support material before further post-processing.

Applications: PolyJet produces smooth parts that may be almost any shore hardness. As such, common uses for PolyJet are cosmetic prototyping, fit testing, simulating overmolding, and flexible parts for industries such as dental, medical, aerospace, automotive, and more.

MultiJet

Materials: Just as PolyJet, MultiJet uses thermoset resins that are curable via UV light. These resins differ, however, in that they start as an uncured solid that must be heated prior to  deposition. MultiJet also can only print one model material at a time, so simulation overmolding and digital materials cannot be achieved.

deposition. MultiJet also can only print one model material at a time, so simulation overmolding and digital materials cannot be achieved.

Process: Once the resin has reached a liquid state, the material is deposited in droplet form from a print head made of hundreds of holes. A UV light then passes over the layer to cure it. As layers are built, they chemically bond to each other and reduce the visibility of layer lines. Once completed, the part is taken from the build platform, put in an oven to melt its support material, and is ready for further post-processing.

Applications: MultiJet 3D printing is capable of simulating the appearance of injection molded parts. Due to this, it is commonly used for cosmetic prototyping, fit testing, and functional parts, especially in terms of parts with small intricate components. It can be found in the medical, dental, aerospace, and jewelry industries.

Stereolithography (SLA)

Materials: SLA is another 3D printing method that uses liquid thermoset resins to create parts. These are cured by a high-powered UV laser. As opposed to PolyJet and MultiJet, SLA does not  use a different material for support structures. Rather, support structures are built from the model material, which makes removal a bit more challenging.

use a different material for support structures. Rather, support structures are built from the model material, which makes removal a bit more challenging.

Process: The build tray, which is contained within a vat, is first coated with a layer of liquid resin. Rotating mirrors then guide the UV laser over the resin to selectively cure it. With each new layer, more resin is added to the tank so that by the time the part is completed, it will have become submerged in uncured resin. After completion of the final layer, the part is scraped from the build tray and its supports are manually clipped off before it is rinsed and placed in a final curing chamber. Further post-processing continues after this hardening cycle.

Applications: Parts made via SLA are typically brittle, so SLA is best suited for making cosmetic prototypes and concept models. It has been used in the electric, automotive, and investment casting industries due to its ability to produce fine details with great accuracy and aesthetic.

Selective Laser Sintering (SLS)

Materials: SLS parts are made from thermoplastics that have been ground into a fine powder. These materials are commonly from the Nylon family of plastics and may be combined with  carbon fiber, glass, or aluminum to boost their mechanical properties. Some flexible materials are available as well.

carbon fiber, glass, or aluminum to boost their mechanical properties. Some flexible materials are available as well.

Process: A layer of powdered thermoplastic material is spread over the build platform, which is enclosed in a heated chamber of inert gas. A high-powered laser is then used to selectively sinter the powder together. More layers are added until the part is complete. Due to the nature of depositing the powder, the finished part will be encased inside a type of powder cake from where the unsintered powder has condensed around the part over the length of the process. This cake must be manually removed before the part can be further cleaned of excess powder and finished.

Applications: Due to not needing support structures, SLS is often used for rapid prototyping as well as functional parts and high temp applications. It is primarily used in the aerospace, automotive, healthcare, medical, and electric industries.

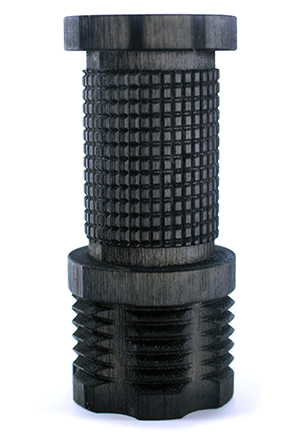

Direct Metal Laser Sintering (DMLS)

Materials: Powdered materials are also used in DMLS 3D printing, but this technology only involves metals, such as aluminum, steel, brass, titanium, and more. These powdered metals  offer the same mechanical properties as cast metals, including strength, weldability, ductility, and heat and corrosion resistance. Some DMLS metals are also biocompatible.

offer the same mechanical properties as cast metals, including strength, weldability, ductility, and heat and corrosion resistance. Some DMLS metals are also biocompatible.

Process: DMLS works in the same fashion as SLS. The powdered metal is spread over the build platform, which is enclosed in a controlled atmosphere of inert gas. A laser is directed at the powder and melts the powdered particles together into the desired layer shape. This process is repeated until the part is completed and can be removed for a heat-treat cycle, removal of support structures, and further post-processing.

Applications: Depending on which metal is used, most DMLS parts are strong and high heat resistant to the point they can be used for custom components in the aerospace, automotive, dental, and medical industries. With many other superb mechanical properties offered in DMLS parts, they are also commonly used for cosmetic prototyping and fit testing.

3D Printing at 3 Space

Here are 3 Space, we offer multiple manufacturing options to suit your production needs. Our team of experienced engineers are happy to help you with any questions or concerns you have regarding our various technologies and services offered. For more information or to get a quote, contact us today.