3D laser scanning is a fast and reliable way to create digital design files from existing parts, prototypes, or landscapes. It is used in many industries to streamline the design and production process. In this article, we will cover how industrial 3D laser scanning works, its applications, and the benefits and drawbacks of this technology.

What is 3D Laser Scanning?

What is 3D Laser Scanning?

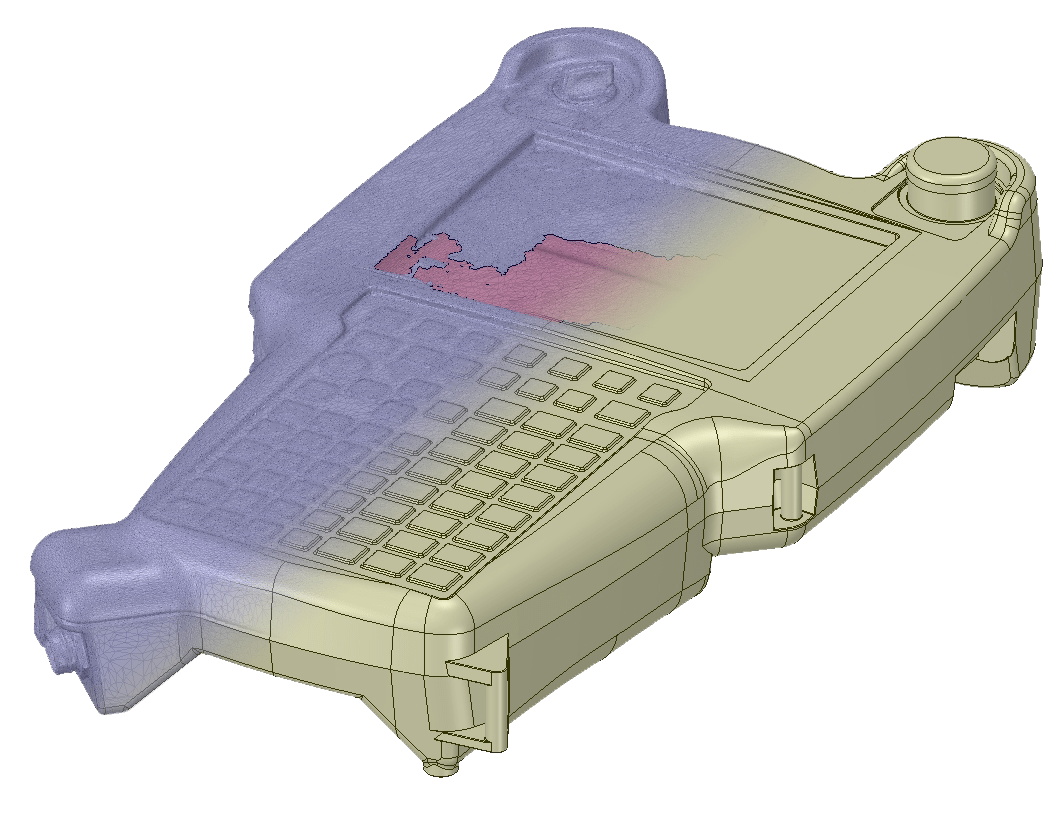

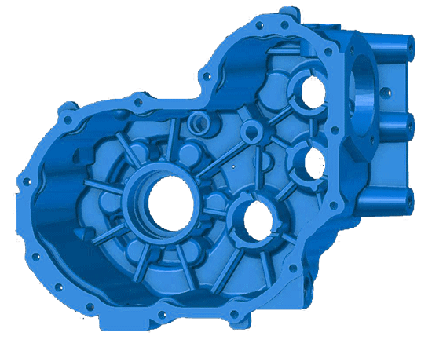

3D laser scanning is a type of digital modeling technology that creates accurate 3D models using laser light and simple mathematics. Depending on the 3D laser scanner, either a laser point or laser line is directed at the object to be scanned. Specialized software then uses either triangulation or time of flight to calculate and record data points where the laser comes in contact with the object’s surface. These points are rendered as cartesian coordinates (X, Y, and Z planes). Typically, thousands or hundreds of thousands of data points are recorded from different angles until a full 360° scan is constructed. Upon completion, this looks like a cluster of data points, called a point cloud, which provides engineers with the information to make a mesh and/or CAD file of the object.

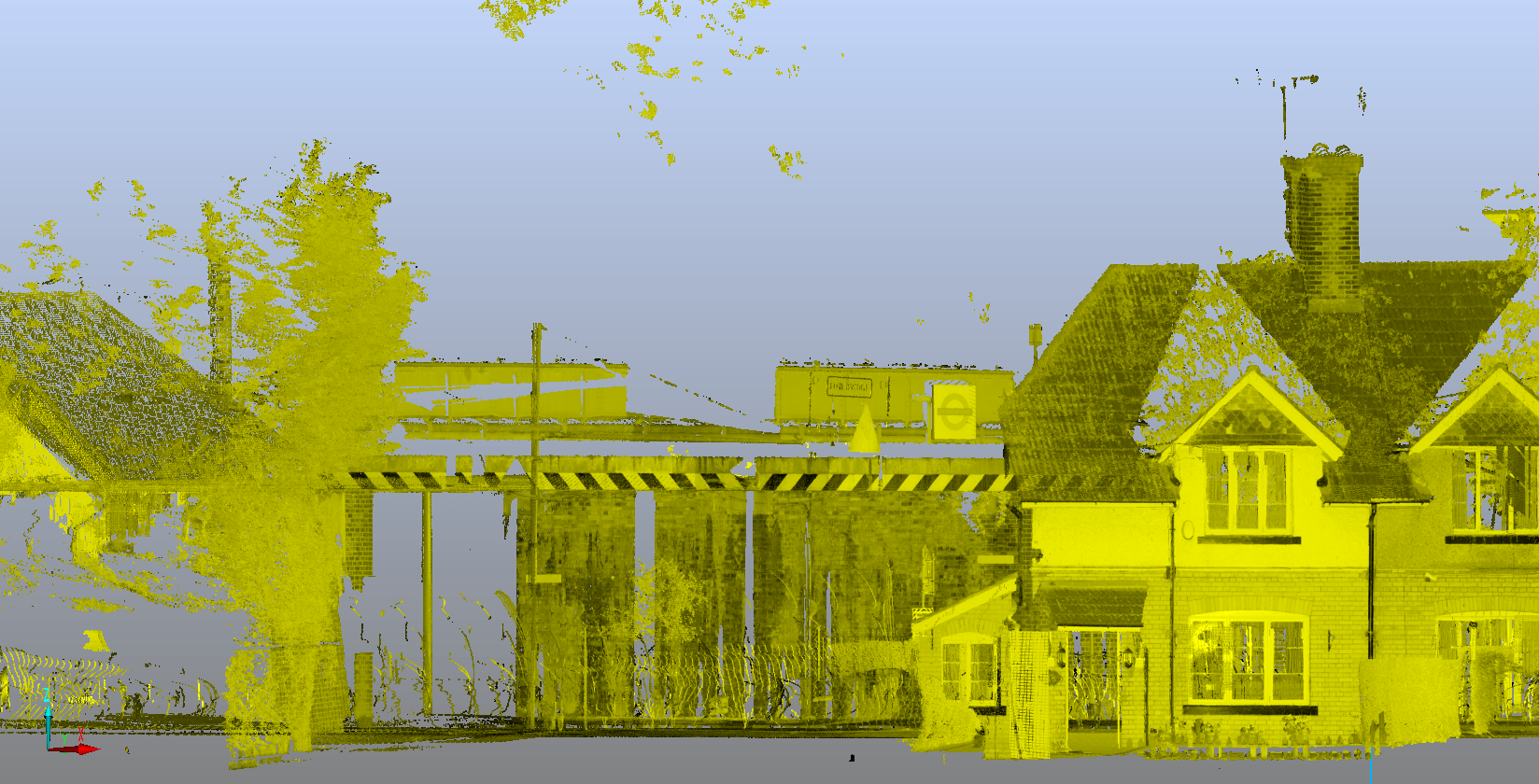

This technology is useful for a variety of applications, including reverse engineering, quality control and assurance, dimensional analysis, and surveying. Specifically, parts may be scanned and digitally rendered to alter handmade prototypes, recreate legacy parts, design aftermarket  parts, and much more. Outdoor use can span a broad spectrum of applications as well, including surveying construction sites, facilities, and archaeology digs and creating video game terrain.

parts, and much more. Outdoor use can span a broad spectrum of applications as well, including surveying construction sites, facilities, and archaeology digs and creating video game terrain.

Below, we’ll detail the general advantages and disadvantages you can expect with 3D laser scanning. Though the principle will be the same, keep in mind that specific aspects about these items may change depending on the exact 3D laser scanner you plan to use and how and where it is to be used.

Advantages of 3D Laser Scanning

1. Fast & Thorough

1. Fast & Thorough

Other measuring technologies, such as CMM, hand tools, and traditional surveying devices, only measure one data point at a time, making them tedious and time-consuming. 3D laser scanning, on the other hand, can record thousands to tens of thousands of data points per second as the laser is moved over the surface of the object or terrain. This enables scans to be completed within hours or days depending on the scale of what you are scanning, meaning your project can progress at an accelerated rate. Additionally, because such a great density of data points are collected with ease, 3D laser scanning provides a more thorough, detailed picture than can be achieved with traditional methods. As such, you can be sure all the information you need has been collected at once.

2. Accurate

Depending on the environment in which the scan is conducted and the specifics of the 3D laser scanner, an accuracy of 0.002-0.197” may be achieved. This high level of accuracy helps ensure that measurements are correct the first time so that less work is needed to complete subsequent steps in design and production.

3. Non-Contact

Because 3D laser scanning is an optical-based technology, there is no need for the scanner to touch the object. This can be helpful when seeking to measure small, intricate, or fragile features that may be distorted or damaged when touched. Distorted objects will likewise yield incorrect measurements, so 3D laser scanning is suggested in such cases.

4. Cost-Effective

With less time and labor being spent during the measurement acquisition and design iteration steps, 3D laser scanning is substantially more cost-effective than most other measuring technologies. Furthermore, 3D laser scanning is affordable because it can easily be outsourced to a company that specializes in 3D scanning services. This can reduce costs related to labor and operator training.

5. Safe

Worker safety is the primary concern for construction sites, and 3D laser scanning can improve on this aspect for surveying. The portable 3D laser scanners used for surveying can record accurate measurements from any distance up to several hundred meters. This can help keep operators safe when the survey area is dangerous due to topography or toxic conditions, such as chemical or nuclear facilities, and proximity must be closely monitored. The speed of this technology also reduces the time that operators may be exposed to such conditions.

Disadvantages of 3D Laser Scanning

1. Line of Sight

Given the optical nature of 3D laser scanning, it is impossible to measure any surface that is out of the scanner’s line of sight. This means that hidden or internal geometry that is not visible to the scanner is unable to be measured. Scans are taken from many different angles in order to ensure a complete model, but complex geometry may still prove to be a problem, such as commonly occurs with holes or threads. For measuring objects with hidden geometry, we recommend using a CT scanner instead.

2. Ambient Light

2. Ambient Light

Because 3D laser scanners read the light of a laser in order to record data, ambient light may blend with the laser and interfere with the scan’s accuracy. Depending on the severity of this interference, the scan may be noisy or even unusable. As such, it is recommended that parts be scanned in a separate room where lighting can be monitored and controlled. For outdoor use, superb scans may be more difficult to obtain due to various weather conditions, including ambient temperature and humidity.

3. Initial Cost

If you do not choose to outsource your 3D laser scanning, it can be quite expensive. On average, industrial 3D laser scanners cost anywhere from $50,000 to $150,000. This does not include set up accessories or operator training. Training a worker to operate the scanner and software and turn the scan into a usable model is much more expensive than outsourcing.  However, if you are planning to perform 3D laser scanning on a regular basis, this approach may actually be the most beneficial option.

However, if you are planning to perform 3D laser scanning on a regular basis, this approach may actually be the most beneficial option.

3D Scanning at 3 Space

Here at 3 Space, we offer several 3D scanning technologies, including our Faro laser scanner. Our Faro scanner is mounted to a movable arm that allows our engineers to have greater control over data acquisition. It is also equipped with a touch probe that may be used separately or in tandem with the laser to provide superb results. For more information about our 3D scanning services or to receive a quote, contact us today.