This post is part of our Injection Molding Design Guide series.

Ribs can be instrumental to your part’s structural success. If used correctly, you can avoid the main problems caused by walls being too thick and abrupt changes in wall thickness. In this article, we’ll discuss what ribs are, what they’re used for, and their recommended dimensions.

What is a Rib?

What is a Rib?

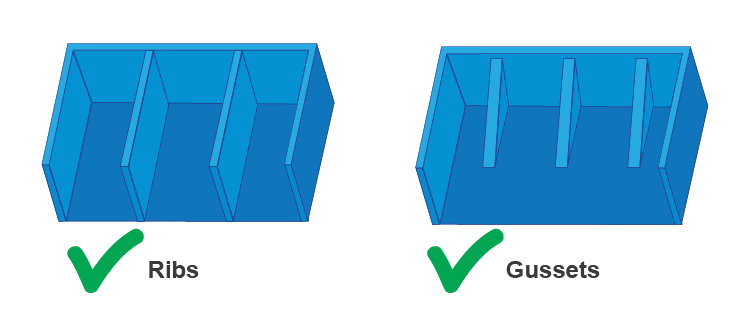

Ribs are thin wall-like structures that add support and rigidity to injection molded parts. They are thinner than primary walls and are used to support these walls, as well as bosses, by running perpendicular to these structures. Ribs are often used to replace thick wall sections to avoid sink marks, warp, and voids. By placing ribs in a load bearing direction, such as long unsupported stretches of your part, instead of making a section thicker, you can retain the support and rigidity you want and eliminate problems caused by thick walls.

Recommended Dimensions

To prevent problems from arising, plastic rib design must adhere to certain proportions. These dimensional ratios are detailed below.

To prevent problems from arising, plastic rib design must adhere to certain proportions. These dimensional ratios are detailed below.

Height

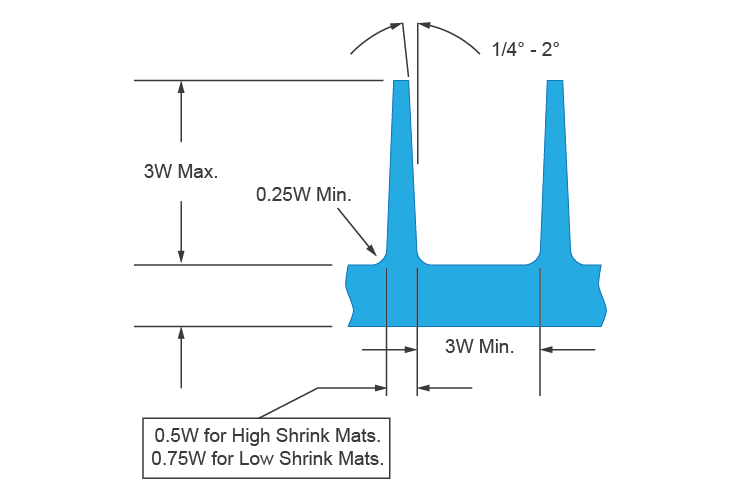

Rib height should not exceed 3 times the thickness of the primary wall. This height cap is recommended because if your ribs are too tall, they can break during use or ejection from the mold. If damage occurs during ejection of tall ribs, it is likely due to draft angles tapering them to slivers at their tips. Ideally, you want to keep your ribs as short as possible while still being functional.

An additional problem that this combination of tall ribs and draft causes is that the plastic may not be able to reach the tip of the rib. This can cause voids if the plastic can’t flow into the very tip of the rib. Deep ribs can also be expensive to tool. To avoid these problems, you can use several short ribs in place of one tall rib. This can better distribute the stress and allow you to keep rib height proportionate while retaining support.

Width

Thick ribs can result in huge problems in your part. If a rib is too thick, the point where it attaches to the primary wall or boss will be thickened as well. This can easily cause sink marks, warp, and voids where there is this excess material. In particular, sinks are visible indicators of bad design, which will affect the appearance of your finished part. If severe enough, sinks and voids can reduce a part’s strength as they become concentrated centers of stress. To prevent these problems, it is recommended that your rib’s width fall between 0.5 and 0.75 times the primary wall’s thickness.

When selecting a rib width, it is important to keep in mind that shrink rate is not the same for all materials. High shrink plastics should be made thinner, while low shrink plastics can be made thicker. Low shrink materials are less likely to cause sink or warp because they do not exert as much pull on the surface or adjacent thin walls as high shrink materials do. You may consider making your ribs thinner based on your part’s intended use or desired cosmetics, but thin ribs are more likely to break.

Radii

The base of a rib should always be rounded with a radius to prevent an area of concentrated stress in the part. Sharp corners also hamper the plastic’s flow rate down into the rib, meaning it may not be able to fill all the way before the material starts to cool, which will cause voids. For these reasons, a rib’s base should have a radius 0.25-0.5 times the width of the primary wall, with the minimum radius being 0.010 inches.

Spacing

Even though multiple ribs add more support, you do not want to have so many that they crowd together. Ribs should be spaced no closer than their height, which is a maximum of 3 times the primary wall thickness. If ribs are closer than that, you run the risk of the ribs not being able to cool quickly. This means the part will have to stay in the mold longer before it can be ejected, which will increase your cycle time and your part cost. Another reason spacing is important is that ribs that are too close together will make it so there are thin sections of your mold. These are prime areas for damage to the mold to occur.

Draft

As with the majority of surfaces of injection molded parts, ribs must be drafted. Draft is especially important for ribs so that they can be removed without damage or breakage. A draft angle of 0.25-2 degrees, with 0.5-1 degrees being the most commonly used, should be applied to each side of the rib.

Gussets

Gussets

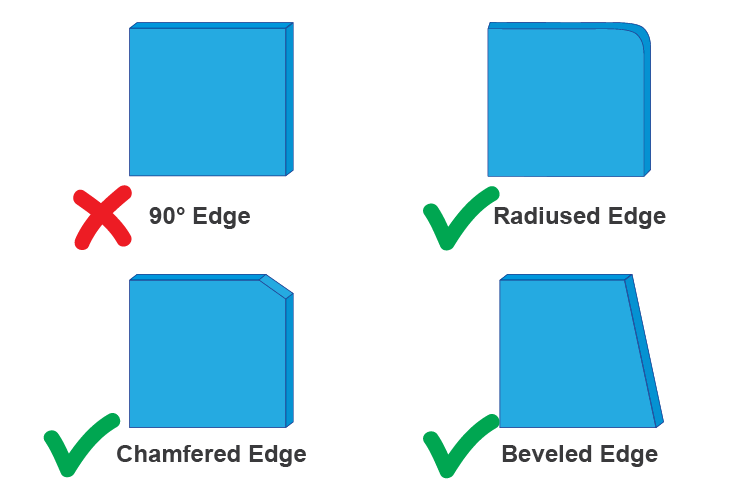

Gussets are a subset of ribs that are often used to support bosses, though they can support walls and other ribs as well. They follow the same design recommendations as all ribs except for their corners. Regular supporting ribs often connect wall-to-wall, and they do not stop at a sharp angle. Gussets are ribs that do not stretch from wall to wall. Rather, they are usually triangular. If a gusset is not triangular, you must ensure that its unconnected corner is rounded, with either a radius, bevel, or chamfer. Sharp angles can make air pockets form when the plastic tries to fill the gusset. This will result in voids in the part, thus possibly weakening the structure. If rounded corners are used, this problem can be avoided.

Design at 3 Space

Here at 3 Space, we can assist you with many manufacturing services, including injection molding, part design and inspection, 3D scanning and printing, and more. Whether you are uncertain if your design is ready to be injection molded or you just need a second pair of experienced eyes to look over it, our engineers can assess your design and make suggestions and changes. For more information, contact us here.